7

GB

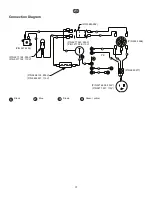

Spraying technique

Hold the paint spray gun upright and maintain a constant

distance of about 3 - 20 cm to the object being sprayed.

Move the paint spray gun evenly either from side to side or up

and down. If the gun is moved evenly, it will produce an even

surface finish. No runs will occur if the speed is correct.

Always start spraying away from the object and avoid stopping

spraying whilst still on the object.

Note:

If the round jet setting is used, the distance may be

increased according to the size of the object being sprayed.

• In case of excessive paint mist formation, adjust

the air and material flow respectively and alter the

distance from the object.

Right

3 - 20 cm

9

Wrong

Excessive paint mist formation, uneven surface finish.

10

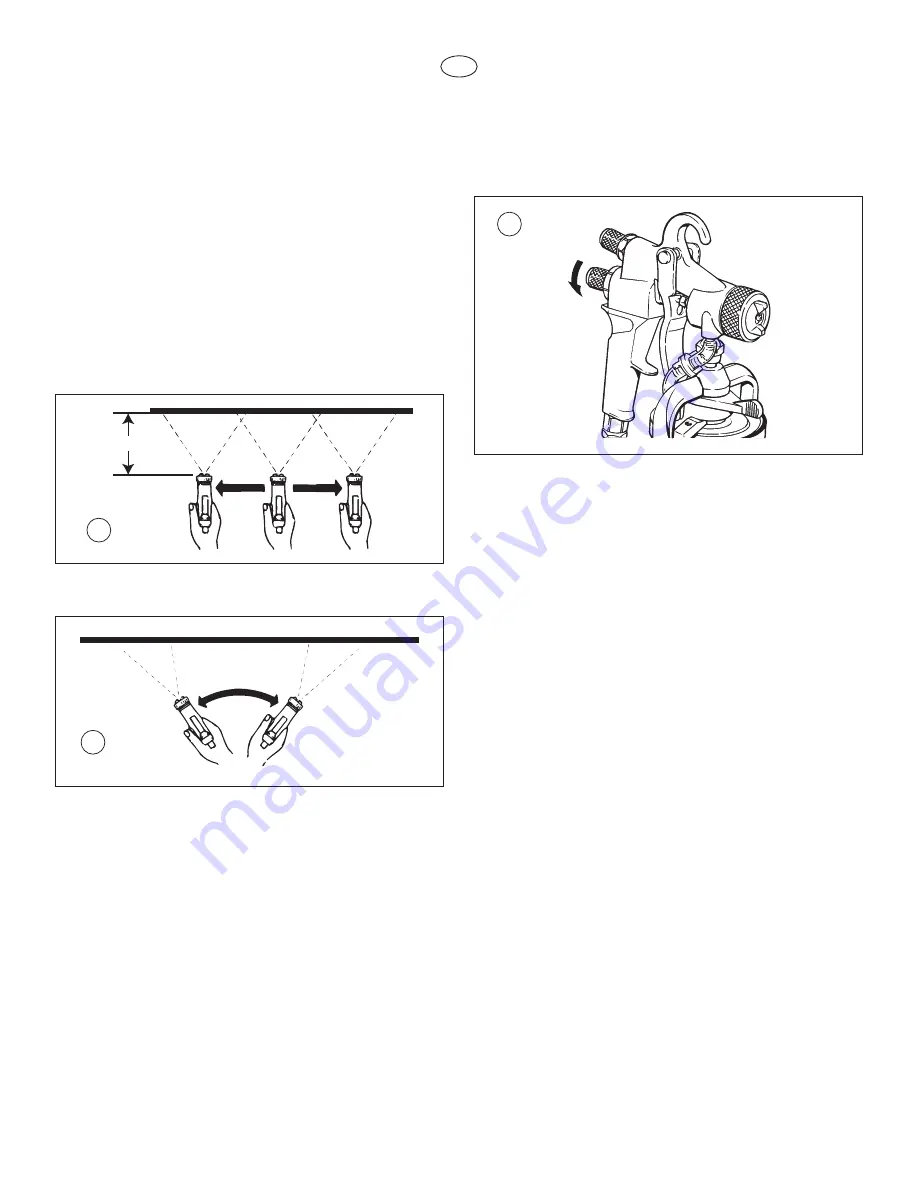

Breaks in work

• Turn the material regulating knob to the right as far as it

will go (fig. 11).

This will secure the paint spray gun against unintentional

operation.

11

• Switch the unit off.

Finishing work and cleaning the unit

1. Switch the unit off.

2. Hold the paint spray gun in the original container. Press

the trigger to release the pressure in the spray gun

container.

3. Undo the paint container closing lever and remove the

container.

4. Empty the remaining coating material into the original

container.

5. Fill the spray gun container with solvent or water and fit

onto the spray gun.

Only use solvents with a flash point above 21 °C.

6. Shake the paint spray gun well.

7. Switch the unit on and spray the solvent or water into an

open container.

Caution! Never spray into a container with only a

small opening (bunghole)! See safety regulations.

8. Repeat this procedure until the solvent or water coming

out of the tip is clear.

Then empty the paint container completely.

Caution! Never leave solvents in the spray gun

container; this may cause pressure to build up in the

container.

Always keep the paint container seal clean of left over

coating material and check regularly for signs of damage.