34

Finish 270 / 250

GB

safety regulatIons

1.8

PReVentIOn OF OccuPAtIOnAl IllneSSeS

Protective clothing, gloves and possibly skin protection cream

are necessary for the protection of the skin.

Observe the regulations of the manufacturer concerning coa-

ting materials, solvents and cleaning agents in preparation,

processing and cleaning units.

1.9

MAx. OPeRAtInG PReSSuRe

The permissible operating pressure for the spray gun, spray

gun accessories, unit accessories and high-pressure hose

must not fall short of the maximum operating pressure of 25

MPa (250 bar or 3625 psi).

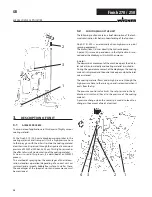

1.10

HIGH-PReSSuRe HOSe (SAFety

InStRuctIOnS)

An electrostatic charging of spray guns and the high-pressure

hose is discharged through the high-pressure hose. For this

reason the electric resistance between the connections of the

high-pressure hose must be equal to or lower than 1 MΩ.

Only use WAGNER original-high-pressure

hoses in order to ensure functionality, safety

and durability.

1.11

electROStAtIc cHARGInG (FORMAtIOn OF

SPARkS OR FlAMeS)

Electrostatic charging of the unit may occur

during spraying due to the flow speed of

the coating material. These can cause sparks

and flames upon discharge. The unit must

therefore always be earthed via the electrical

system. The unit must be connected to an

appropriately-grounded safety outlet.

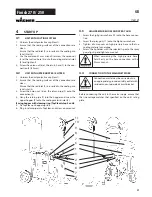

1.12

uSe OF unItS On BuIldInG SIteS And

WORkSHOPS

The unit may only be connected to the mains network via a

special feeding point with a residual-current device with INF

≤ 30 mA.

1.13

VentIlAtIOn WHen SPRAyInG In ROOMS

Adequate ventilation to ensure removal of the solvent vapors

has to be ensured.

1.14

SuctIOn InStAllAtIOnS

The are to be provided by the unit user in accordance with the

corresponding local regulations.

1.15

eARtHInG OF tHe OBject

The object to be coated must be earthed.

(Building walls are usually earthed naturally)

1.16

cleAnInG tHe unIt WItH SOlVentS

When cleaning the unit with solvents, the

solvent should never be sprayed or pumped

back into a container with a small opening

(bunghole). An explosive gas/air mixture can

arise. The container must be earthed.

1.17

cleAnInG tHe unIt

Danger of short-circuits caused by water in-

gression!

Never spray down the unit with high-pressu-

re or high-pressure steam cleaners.

1.18

WORk OR RePAIRS At tHe electRIcAl

equIPMent

These may only be carried out by a skilled electrician. No liabi-

lity is assumed for incorrect installation.

1.19

WORk At electRIcAl cOMPOnentS

Unplug the power plug from the outlet before carrying out

any repair work.

Summary of Contents for Finish 250

Page 19: ...19 Finish 270 250 10 9 Schaltplan d reparaturen am ger t...

Page 24: ...24 Finish 270 250 ersatzteile und zubeh r Ersatzteilbild Pumpenaggregat d...

Page 48: ...48 Finish 270 250 GB Repairs at the unit 10 9 Connection diagram...

Page 53: ...53 Finish 270 250 GB Spare parts diagram pump aggregate Spare parts and accessories...

Page 77: ...77 Finish 270 250 10 9 Sch ma lectrique F R parations sur l appareil...

Page 107: ...107 Finish 270 250 10 9 Elektrisch schema Reparaties aan het apparaat NL...

Page 112: ...112 Finish 270 250 Onderdelenafbeelding pompaggregaat NL Accessoires en onderdelen...

Page 118: ...118 Finish 270 250 NL CE Verklaring van overeenstemming...

Page 119: ...119 Finish 270 250 NL CE Verklaring van overeenstemming...