41

Finish 270 / 250

GB

5

SPRAyInG tecHnOlOGy

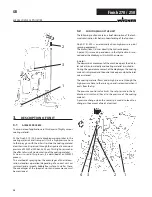

Move the spray gun evenly during the spraying process. If this

is not observed, an irregular spraying appearance will be the

result. Carry out the movement with the arm, not with the

wrist. A parallel distance of approx. 30 cm between the tip and

the surface to be coated should always be observed. The late-

ral limitation of the spray fan should not to be too distinct. The

edge of spraying should be gradual to facilitate overlapping of

the next coat. The spray gun should always be held at an angle

of 90° to the surface to be coated. A spray fan aimed obliquely

at the surface to be coated leads to an unwanted spray cloud.

To achieve perfect surfaces at varnishing works, special acces-

sories are available at Wagner, e.g. FineFinish tips or an AirCoat

gun set. Your Wagner dealer will advise you.

6

HAndlInG tHe HIGH-PReSSuRe

HOSe

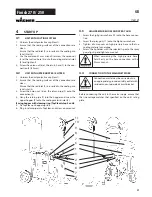

The high-pressure hose is to be handled with care. Avoid sharp

bending or kinking. The smallest bending radius amounts to

about 20 cm.

Do

not drive over

the high-pressure hose. Protect against

sharp objects and edges.

Danger of injury through leaking high-

pressure hose. Replace any damaged high-

pressure hose immediately.

Never repair defective high-pressure hoses

yourself!

When using the high-pressure hose while

working on scaffolding, it is best to always

guide the hose along the

outside

of the scaf-

folding.

6.1

HIGH-PReSSuRe HOSe

The unit is equipped with a high-pressure hose specially sui-

ted for diaphragm pumps.

Only use WAGNER original-high-pressure

hoses with internal heating in order to ensure

functionality, safety and durability.

7

InteRRuPtIOn OF WORk

1. Turn pressure regulating knob

three revolutions

to the

left

.

2 Open relief valve (2)

valve position

(circulation)

3. Switch off the unit

4. Pull trigger guard of spray gun to decrease the pressure of

the high pressure hose and the spray gun.

5. Secure the spray gun, refer to the operating manual of the

spray gun.

6. Remove tip from tip holder and store the tip in a small ves-

sel with suitable cleaning agent.

7. Leave the suction system immersed in the coating materi-

al or immerse it in the corresponding cleaning agent. The

suction filter and unit should not dry out.

8. Cover the material container in order to prevent the paint

from drying.

In using quick-drying or two-component

coating materials, do not fail to rinse unit

through with a suitable cleaning agent duri-

ng the processing period.

sprayIng technIque / handlIng the hIgh-pressure hose / InterruptIon of work

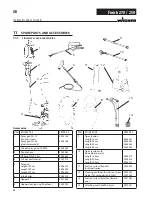

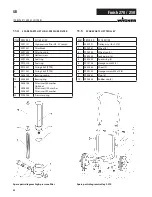

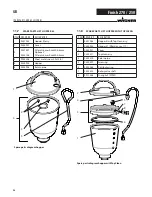

Summary of Contents for Finish 250

Page 19: ...19 Finish 270 250 10 9 Schaltplan d reparaturen am ger t...

Page 24: ...24 Finish 270 250 ersatzteile und zubeh r Ersatzteilbild Pumpenaggregat d...

Page 48: ...48 Finish 270 250 GB Repairs at the unit 10 9 Connection diagram...

Page 53: ...53 Finish 270 250 GB Spare parts diagram pump aggregate Spare parts and accessories...

Page 77: ...77 Finish 270 250 10 9 Sch ma lectrique F R parations sur l appareil...

Page 107: ...107 Finish 270 250 10 9 Elektrisch schema Reparaties aan het apparaat NL...

Page 112: ...112 Finish 270 250 Onderdelenafbeelding pompaggregaat NL Accessoires en onderdelen...

Page 118: ...118 Finish 270 250 NL CE Verklaring van overeenstemming...

Page 119: ...119 Finish 270 250 NL CE Verklaring van overeenstemming...