21

FinishControl 5500

EN

14

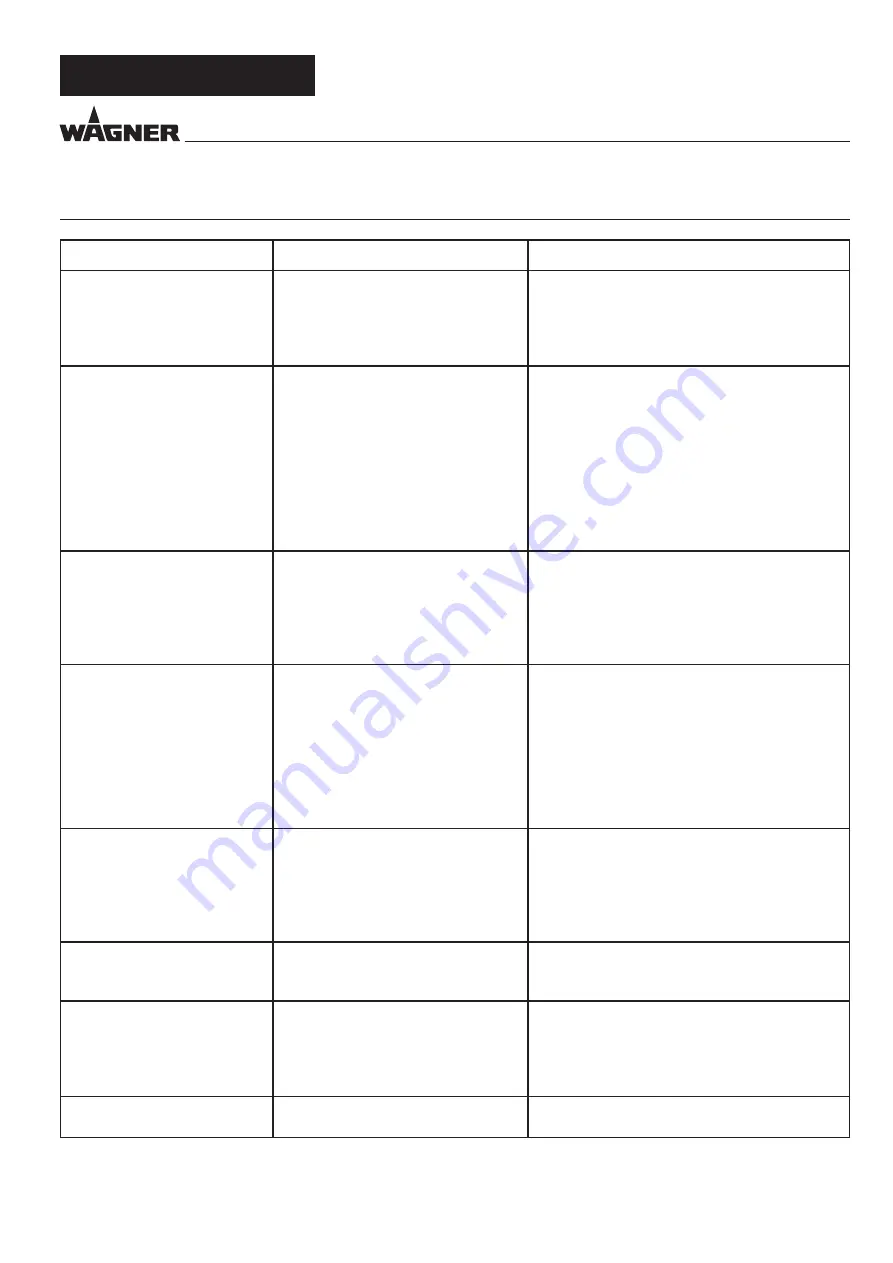

CORRECTION OF MALFUNCTIONS

MALFUNCTION

CAUSE

REMEDY

The unit will not start

•

No mains voltage

•

Device overheated

•

Check

•

Unplug the power plug, let the device cool

down approx. 30 minutes, do not bend the

hose, check the air filter, do not cover the intake

slots

No coating material emerges

from the nozzle

•

Nozzle clogged

•

Material volume setting too low

•

Paint container seal damaged

•

No pressure build-up in container

•

Container empty

•

Ventilation hose loose/damaged

•

Feed tube loose

•

Feed tube / feed tube filter clogged

•

Air vent on feed tube blocked

•

Diaphragm stuck

•

Clean

•

Increase volume

•

Replace

•

Tighten container

•

Refill

•

Insert or replace

•

Insert

•

Clean or use another filter

•

Clean

•

Remove and clean (see section 13.2)

Coating material drips from the

nozzle

•

Air cap, nozzle or needle soiled

•

Spray attachment incorrectly

assembled

•

Nozzle loose

•

Nozzle worn

•

Needle worn or damaged

•

Clean

•

Assemble correctly (see section 12.1)

•

Tighten Union nut

•

Change

•

Replace the needle (service set 2434517)

Atomisation too coarse

•

Material volume too large

•

Nozzle contaminated

•

Viscosity of coating material too high

•

Too little pressure build-up in

container

•

Air filter heavily soiled

•

Amount of air too low

•

Air hose damaged

•

Air cap assembled incorrectly

•

Reduce volume

•

Clean

•

Dilute further

•

Tighten container

•

Change (see section 13.1)

•

Increase volume

•

Check and replace if necessary

•

Snap air cap properly into place (fig. 17)

Spray jet pulsates

•

Coating material in container running

out

•

Nozzle seal worn

•

Air filter heavily soiled

•

Feed tube loose

•

Feed tube / feed tube filter clogged

•

Refill

•

Replace

•

Change (see section 13.1)

•

Insert

•

Clean or use another filter

Coating material causes “paint

tears

•

Too much coating material applied

•

Distance too small

•

Incorrect spray attachment

•

Reduce volume

•

Increase distance

•

Use another spray attachment

Excessive paint mist (overspray)

•

Distance to the object too large

•

Too much coating material applied

•

Amount of air too high

•

Coating substance over-diluted

•

Incorrect spray attachment

•

Reduce distance

•

Reduce volume

•

Reduce volume

•

Reduce degree of dilution

•

Use another spray attachment

Paint in the ventilating hose

•

Diaphragm soiled

•

Diaphragm defective

•

Clean the diaphragm (see section 13.2)

•

Replace the diaphragm (see section 13.2)

CORRECTION OF MALFUNCTIONS

Summary of Contents for FINISH CONTROL 5500

Page 3: ...FinishControl 5500 A B 2 1 1 1 1 3 10 cm 1 2 1 2...

Page 4: ...FinishControl 5500 r 1 q 1 s 1 3 2 2 6 1 5 3...

Page 5: ...FinishControl 5500 3 2 1 2 1 4 5 6 1 2 4 7 8 9 10 5 t 1 3 6 3...

Page 113: ...107 FinishControl 5500 RU 1 1 a b c 2 a b c d e f 3 a b c d e f g...

Page 114: ...108 FinishControl 5500 RU 4 a b c d e f g 5 a b 1 2...

Page 115: ...109 FinishControl 5500 RU 3 4 3 5 6 1 4 13 2 7 8 9 10 11 12 13 14 15 16...

Page 121: ...115 FinishControl 5500 RU 14 30 13 2 12 1 2434517 13 1 17...

Page 125: ...119 FinishControl 5500 RU 4 Wagner 5 18 88677...

Page 126: ...120 FinishControl 5500 RU...

Page 127: ...121 FinishControl 5500 RU...