9

FinishControl 5500

EN

13.2

AIR RELIEF VALVE

If paint has entered the ventilation hose, proceed

as follows:

1. Pull the ventilating hose (Fig. 20, 1) at the top from the

gun body. Screw off the valve cover (2). Remove the

diaphragm (3). Clean all the parts carefully.

CAUTION! The ventilation hose and

diaphragm are only solvent-resistant to a

limited extent. Do not immerse in solvent,

only wipe.

2. Place the diaphragm in the valve cover with the pin facing

forward (Also see the marking on the gun body).

3. Turn the body of the gun upside down and screw on the

valve cover from underneath.

4. Place the ventilating hose on the valve cover and on the

nipple at the gun body.

MAINTENANCE

Warning

If the supply cord of this appliance is damaged, it must only

be replaced by a repair shop appointed by the manufacturer,

because special purpose tools are required.

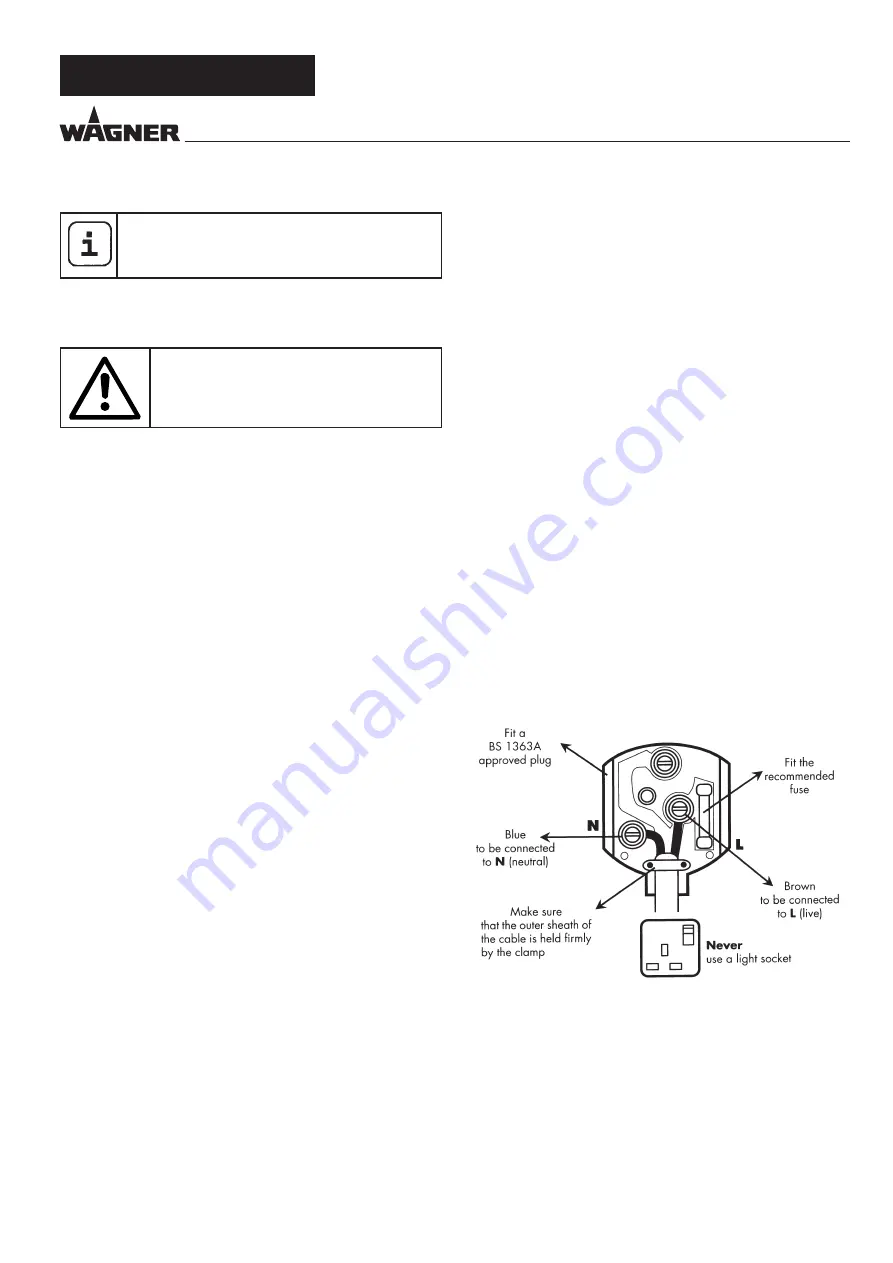

Warning:

Do not connect the blue or brown wire to the earth

terminal of the plug! The wires in this mains lead are coloured

in accordance with the following code:

blue

= neutral

brown

= live

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings identifiying

the terminals in your plug, proceed as follows:

Should the moulded plug have to be replaced, never re-use

the defective plug or attempt to plug it into a different 13 A

socket. This could result in an electric shock.

Should it be necessary to exchange the fuse in the plug only

use fuses approved by ASTA in accordance with BS 1362. 5 Amp

fuses may be used.

To ensure that the fuse and fuse carrier are correctly mounted

please observe the provided markings or colour coding in the

plug.

After changing the fuse, always make sure that the fuse carrier

is correctly inserted. Without the fuse carrier, it is not permissible

to use the plug.

The correct fuses and fuse carriers are available from your

local electrical supplies stockist.

Summary of Contents for FinishControl 5500

Page 1: ...FINISH CONTROL 5500 OPERATING MANUAL wagner group com EN...

Page 3: ...FinishControl 5500 A B 2 1 1 1 1 3 10 cm 1 2 1 2...

Page 4: ...FinishControl 5500 r 1 q 1 s 1 3 2 2 6 1 5 3...

Page 5: ...FinishControl 5500 3 2 1 2 1 4 5 6 1 2 4 7 8 9 10 5 t 1 3 6 3...

Page 17: ...13 FinishControl 5500 EN...

Page 18: ...14 FinishControl 5500 EN...

Page 19: ...15 FinishControl 5500 EN...