12

EN

CLEANUP

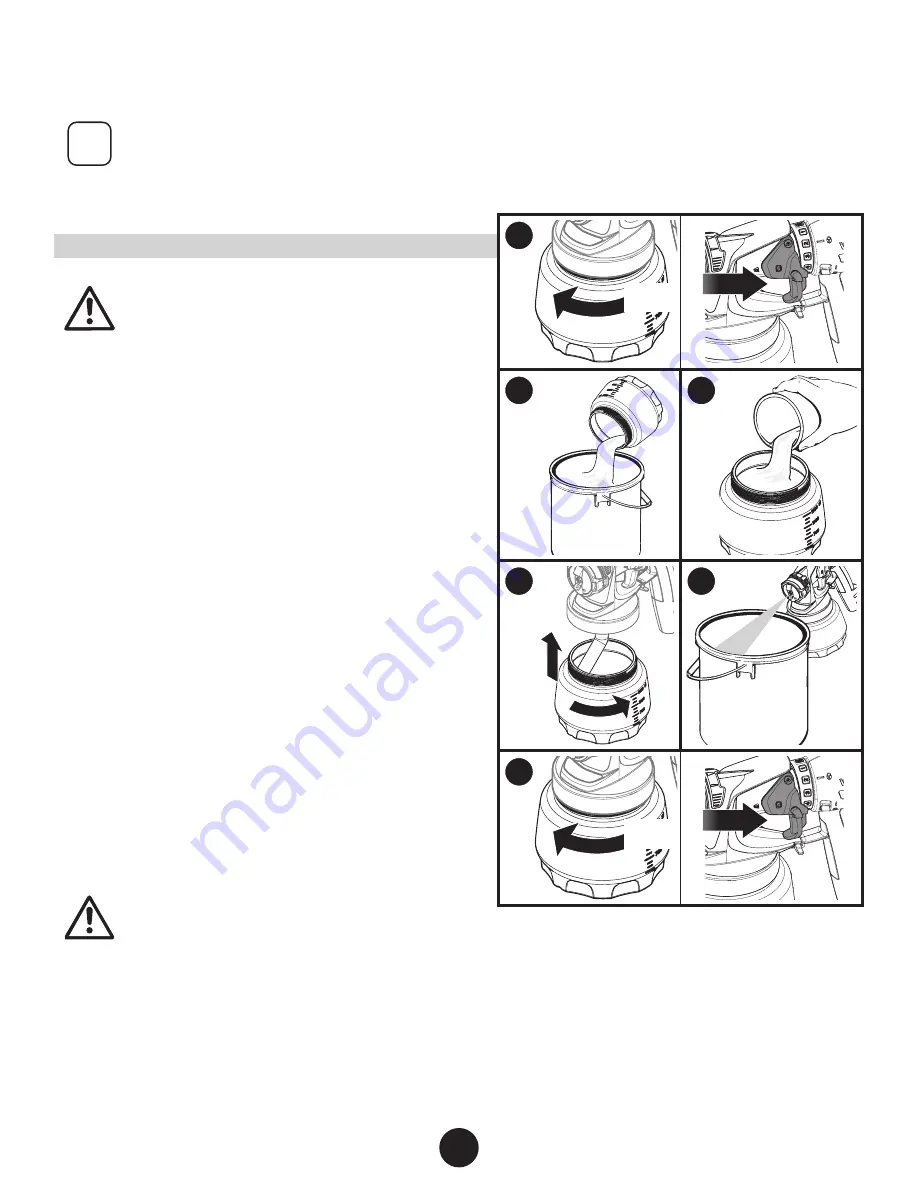

1

1/2

PULL

2

3

4

5

EMPTY WASTE

CONTAINER

6

1/2

PULL

FLUSHING THE UNIT

Special cleanup instructions for use with

flammable solvents (must have a flashpoint

above 100ºF (38ºC):

•

Always flush spray gun outside.

•

Area must be free of flammable vapors.

•

Cleaning area must be well-ventilated.

•

Do not submerge turbine!

1.

Unplug the power cord. Loosen the material container

by 1/2 turn, but do not remove it. This will relieve any

pressure left over in the system.

Pull the trigger so that the material inside the spray nozzle

drains back into the container.

2.

Unscrew the container and remove. Empty any remaining

material back into the material container.

3.

Pour a small amount of the appropriate cleaning solution

into the cup (Water=1/2 full. Mineral spirits=1/4 full).

4.

Attach the cup to the nozzle and plug in the sprayer.

5.

Spray the cleaning solution into a safe area.

While spraying, gently shake the spray gun. This slight

agitation will help break up smaller particles of spray

material.

6.

Unplug the power cord. Loosen the material container

by 1/2 turn, but do not remove it. This will relieve any

pressure left over in the system.

Pull the trigger so that the material inside the spray nozzle

drains back into the container.

Attention

If you cleaned the sprayer using mineral

spirits, repeat steps 1-6 using warm, soapy

water.

i

When cleaning, use the appropriate

cleaning solution (warm, soapy water for

latex materials; mineral spirits for oil-based

materials).

Move on to “Cleanup - Cleaning

the Nozzle”, next page.