English

10

© Wagner Spray Tech - All Rights Reserved

Proper Spraying Technique

STOP

The room you are spraying must be

properly masked in order to prevent

overspray from covering woodwork,

floors or furnishings. Make sure you

have properly masked the room per the

instructions on the enclosed “Taping

Guide”.

If spraying with an air-assisted spray system is new

or unfamiliar to you, it is advisable to practice on a

piece of scrap wood or cardboard before beginning

on your intended workpiece and/or test with water.

Spray Poster

A spray poster is included with your unit. The spray

poster can be adhered to a spraying surface and can

be used for practice. Follow the guidelines on the

poster.

Surface Preparation

All objects to be sprayed should be thoroughly

cleaned before spraying material on them. Areas

not to be sprayed may, in certain cases, need to be

masked or covered.

Spray Area Preparation

The spray area must be clean and free of dust in

order to avoid blowing dust onto your freshly

sprayed surface.

How to Spray Properly

STOP

It is important to keep your arm moving

whenever the gun is being triggered. If

you pause or linger in one spot too long,

too much material will be sprayed on the

surface.

note : Do not pull trigger at any time if the

turbine is not running. This will result in spray

material leaking from the nozzle.

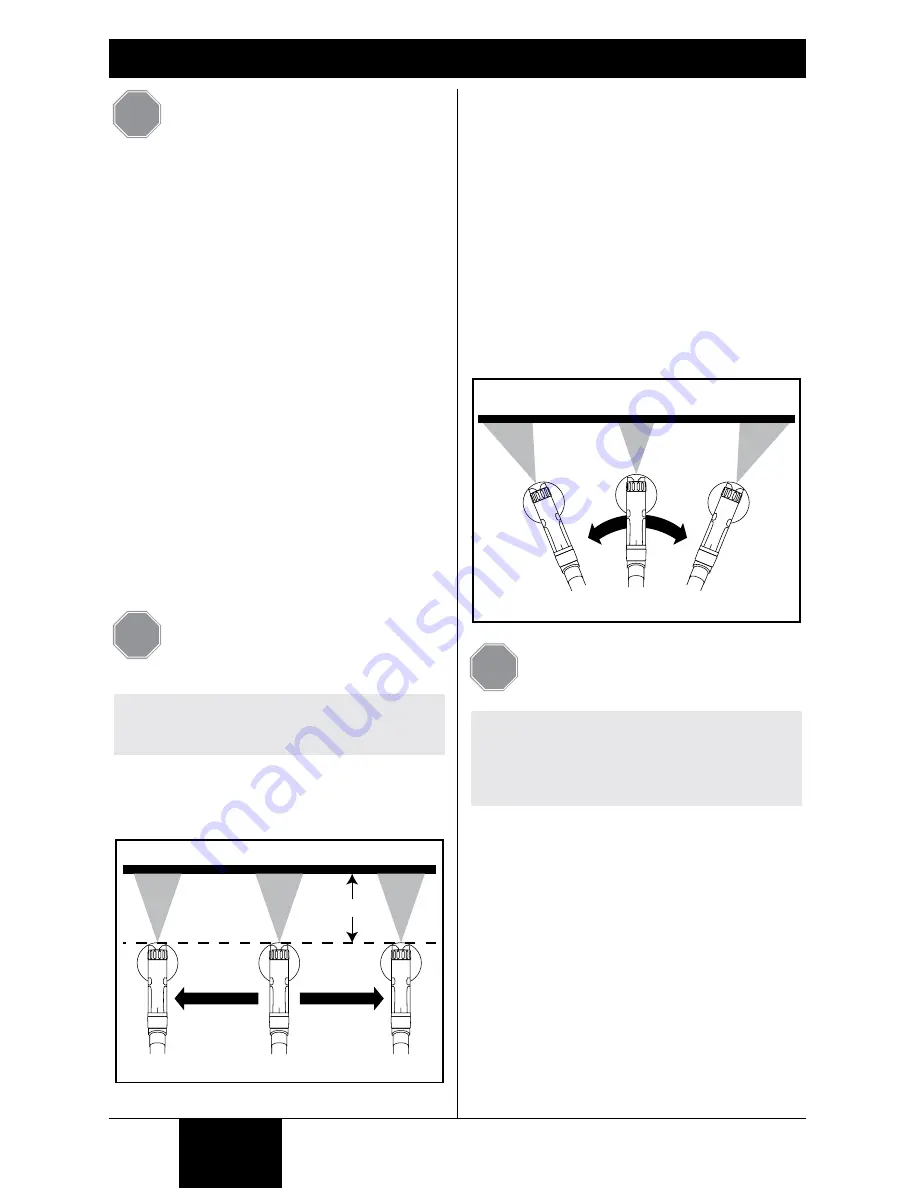

• Spray parallel to the surface with smooth passes

at a consistent speed as illustrated below.

Doing this will help avoid irregularities in the

finish (i. e. runs and sags).

6 - 8 inches

Correct

Even coat throughout

Keep stroke smooth and at an even speed

• Position the spray gun perpendicular to and six

(6) to eight (8) inches from the spray surface,

depending upon the spray pattern size desired.

With reduced material flow and air power, you

can get closer to the spraying surface.

• Always apply a thin coat of material on the first

pass and allow to dry before applying a second,

slightly heavier coat.

• When spraying larger surfaces, overlap each

spray pass by at least 50% This will ensure full

coverage.

• When spraying, always trigger the spray gun

after spray pass has begun and release trigger

before stopping the pass. Always keep the

gun pointed squarely at the spray surface and

overlap passes slightly to obtain the most

consistent and professional finish possible.

Incorrect

Do not flex wrist while spraying.

Light coat

Heavy coat

Light coat

STOP

During a project, periodically wipe the

nozzle tip with a cloth to remove any

dried paint.

note: When you quit spraying for any length of

time, turn the turbine OFF and place the spray

gun into the spray gun holder on the turbine.

When you restart, wipe the nozzle with a damp

cloth to remove any dried paint.