English

© Wagner Spray Tech - All Rights Reserved

13

Cleanup (continued)

Cleaning the nozzle

To Clean the Nozzle:

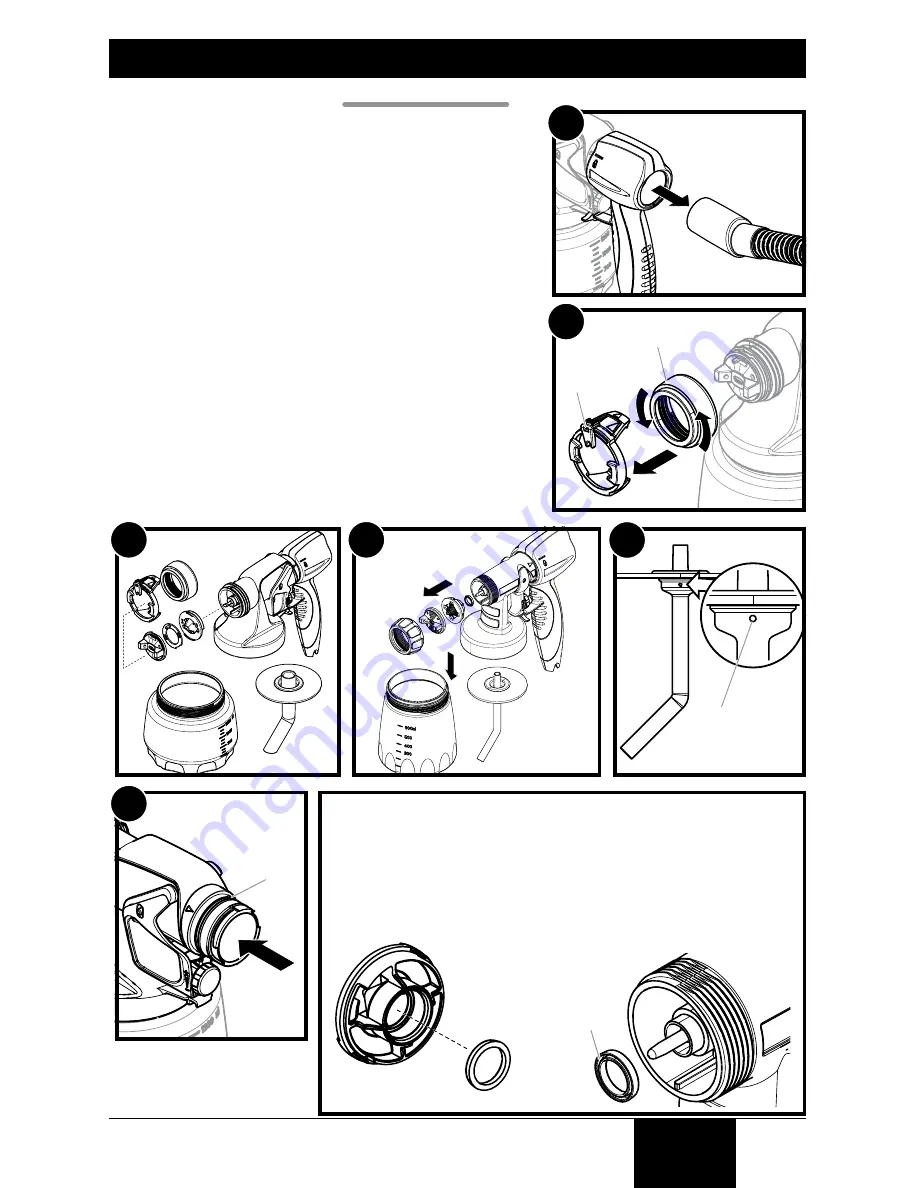

1. Make sure power cord is unplugged. Remove the air

hose from the rear of the spray gun handle.

2. iSpray nozzle only -

a. Remove the adjustment ring (a) carefully from the

connecting nut (b). Loosen the connecting nut.

b. Remove the parts as shown. Clean all parts with a

cleaning brush and the appropriate cleaning solution.

To reassemble, see the instructions on the next page.

3. Detail Finish nozzle only -

a. Unscrew the nut and remove the air cap and nozzle.

Remove the parts as shown*. Clean all parts with a

cleaning brush and the appropriate cleaning solution.

Reassemble all parts when clean**.

4. Clean the air vent (c) on the suction tube with a soft

bristled cleaning brush.

5. Push the tab below the trigger, twist and separate the

spray gun from the handle.

Clean the rear of the nozzle (d) with the appropriate

cleaning solution. Use a thin layer of petroleum jelly to

lubricate the O-ring (e).

(a)

(b)

2a

1

(c)

(d)

(e)

2b

4

5

3a

Nozzle seal (Detail Finish nozzle only)

(*)

The nozzle seal may

become stuck inside the

Detail Finish nozzle when

the nozzle is removed. If this

occurs, make sure to pull it

out.

(**)

It is important that the nozzle

seal inside the nozzle be re-installed

properly. Make sure the cup side of

the seal (the side with the groove) is

facing out towards the front of the

nozzle. Improper installation will cause

leakage and damage to the turbine.

Groove