English

8

© Wagner Spray Tech - All Rights Reserved

Air and Material Controls

Spray performance will depend upon a number of

factors: material thickness, spray pattern selected,

material volume, and air pressure. With any type

of air-assisted spraying, desired spray results will

be achieved through some trial and error while

adjusting some or all of these variables.

Review these pages to learn about the spray controls

and how they can be used to acheive the desired

spray results.

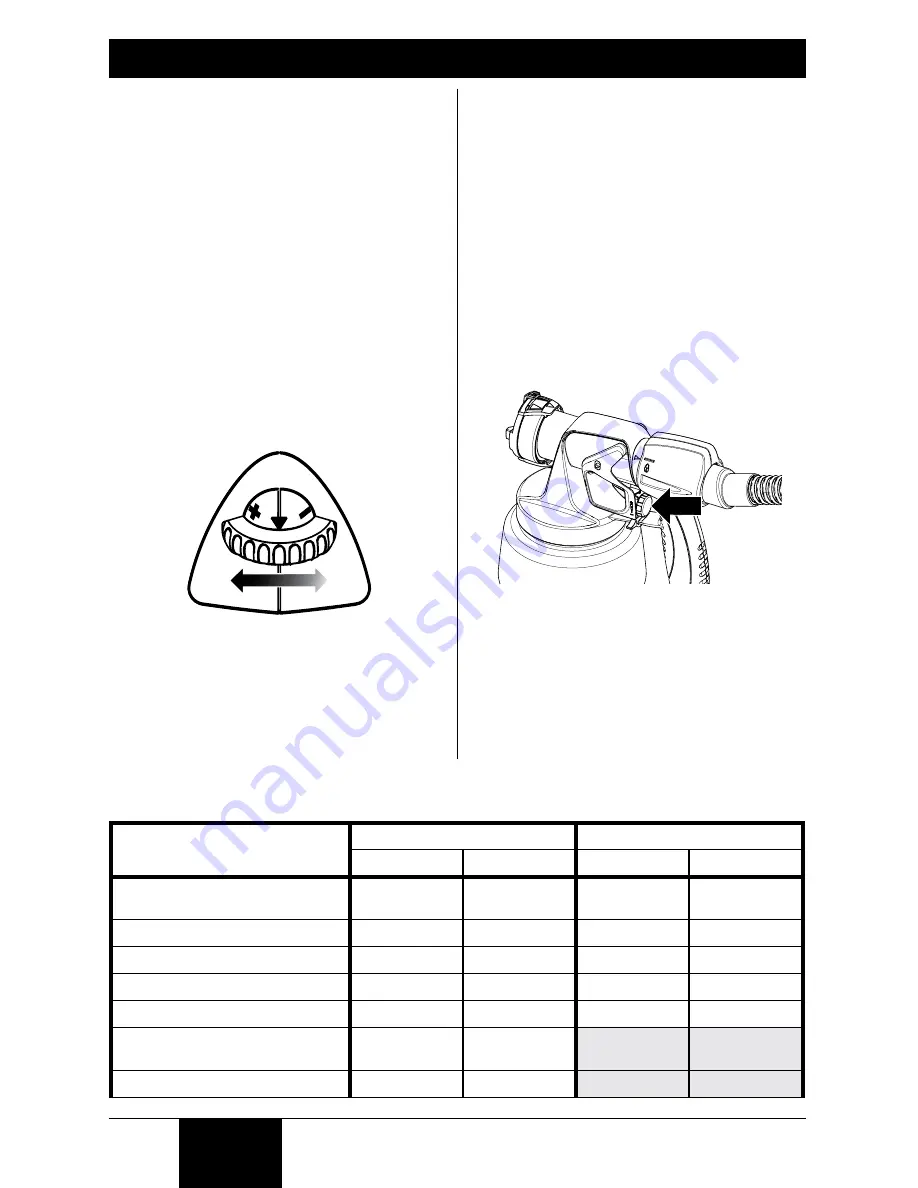

X-Boost™ Power Dial

The X-Boost™ power dial adjusts the level of air

pressure produced by the turbine. The X-Boost™

power dial is factory-set at maximum out of the box.

• A high air power level will result in faster

coverage and a smoother finish with thicker

materials.

• Lowering the air power will result in larger

drops of material being sprayed from the gun,

and will create a slightly rougher finish.

+

-

Tip: The thicker the material you are spraying, the

higher the turbine power you will need.

Tip: For fine-finish work with thinner materials, you

may want to decrease the air power. Spraying a

thinner material at high air power will result in more

overspray. Overspray is sprayed material that does

not stick to the spray surface and bounces back.

Material Flow Adjustment

The material flow adjustment controls the amount

of spray material that is sprayed from the spray gun.

• For thicker materials, it is recommended that

you start with the highest material flow setting

and then gradually decrease the flow to suit

your particular spraying needs.

• For thinner materials, it is recommended that

you start with a low material flow setting, and

then gradually increase the flow to suit your

particular spraying needs.

• The higher the flow setting, the quicker you will

have to work in order to avoid drips and sags in

your spray pattern.

Set the material volume by turning the knob on the

trigger of the spray gun.

Tip: Spraying with the control set too high will

result in a spray pattern that runs and sags (too

much material).

Tip: Spraying with the control set too low will result

in a spray pattern that does not cover (not enough

material).

Tip: To ensure desired results are achieved with the

controls, test your spray pattern on the spray poster

or a scrap piece of wood or cardboard.

Power and Material Settings Guide

Coating

iSpray nozzle

Detail Finish nozzle

Material Flow

air Power

Material Flow

air Power

Transparent / semi-transparent

stains, sealers

Light

Low

Med/Heavy

Low

Lacquers (water based)

Light

Low

Med/Heavy

Low

Solid stains

Med

Low / Med

Med

Low / Med

Polyurethane

Med

Low / Med

Med/Heavy

Low / Med

Oil enamels

Heavy

Med

Heavy

Med-Hi

Latex paints plus primers, Latex

paints

Heavy

Med-Hi

N/A

N/A

Oil or latex primers

Heavy

Med-Hi

N/A

N/A