10

GA 2800EA, GA 2805EA

OPERATING MANUAL

EDITION 12/2008

PART NO. DOC350731

2.6

ESTABLISHMENT OF STATIONARY ELECTROSTATIC SYSTEMS

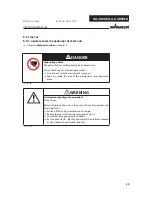

)GNITIONTEMPERATUREOFTHECOATINGMATERIAL

%NSURETHATTHEIGNITIONTEMPERATUREOFTHECOATINGMATERIALISABOVETHEMAXIMUM

SURFACETEMPERATURE

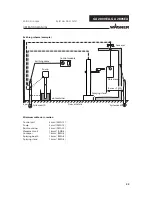

3URFACESPRAYINGELECTROSTATIC

$ONOTSPRAYUNITPARTSWITHELECTROSTATICEGELECTROSTATICSPRAYGUN

-EDIUMSUPPORTINGATOMIZING

4OATOMIZETHEMATERIALUSEONLYWEAKLYOXIDIZINGGASESEGAIR

#LEANING

)FTHEREAREDEPOSITSONTHESURFACESTHEUNITMAYFORMELECTROSTATICCHARGES&LAMESOR

SPARKSCANFORMIFTHEREISADISCHARGE

2EMOVEDEPOSITSFROMTHESURFACESTOMAINTAINCONDUCTIVITY

5SEONLYADAMPCLOTHTOCLEANTHEUNIT

4HESPRAYGUNISACOMPONENTOFASTATIONARYSPRAYINGSYSTEM7HENESTABLISHSTATIONARY

SPRAYINGSYSTEMSSTRICTLYCOMPLYWITHREGULATION%.!MONGOTHERTHINGSITISRE

QUIREDTHATSWITCHONOFHIGHVOLTAGEISONLYPOSSIBLEWITHAKEY"UTITMUSTBEPOSSIBLETO

SWITCHOFFHIGHVOLTAGEWITHOUTANYKEYFORINSTANCEWITHAEMERGENCYSTOPBUTTON

2.7

GERMAN REGULATIONS AND GUIDELINES

a)

BGV A2

Electrical units and equipment

b) BGV D15

Working with liquid ejection devices

c)

BGV D25

Using coating materials

d) CHV 9

Regulations on flammable liquids

e)

CHV 11

Regulations on electrical equipment in Ex areas

f )

BGR 104

Explosion protection rules

g) BGR 132

Avoiding ignition risks

h) BGR 180

Setting up for cleaning with solvents for cleaning workpieces with

solvents

i)

ZH 1/406

Guidelines for liquid ejection devices

j)

BGI 740

Painting rooms and equipment

k)

BGI 764

Electrostatic coating

Note:

All titles can be ordered from Heymanns Publishing House in Cologne or download

from Internet.