26

B_03073

OPERATING MANUAL

VERSION 06/2013

ORDER NUMBER DOC 2312956

Close:

The piston is relieved, and the product valve closes due to the pressure spring which

presses against the product valve tappet. The air valve is then closed, again with a spring

force and mechanical delay.

Additional functions:

The shaping air throttle is used to regulate the shaping air volume, while the atomizing air is

adjusted via an external pressure regulator. The two air streams do not fl ow separately until

downstream of the air valve, so that the pressure of the shaping air corresponds roughly to

that of the atomizing air and so that they infl uence each other during adjustment.

The product connections and the paint channels in the base plate are arranged so that

several guns can run in circulation mode.

5.5

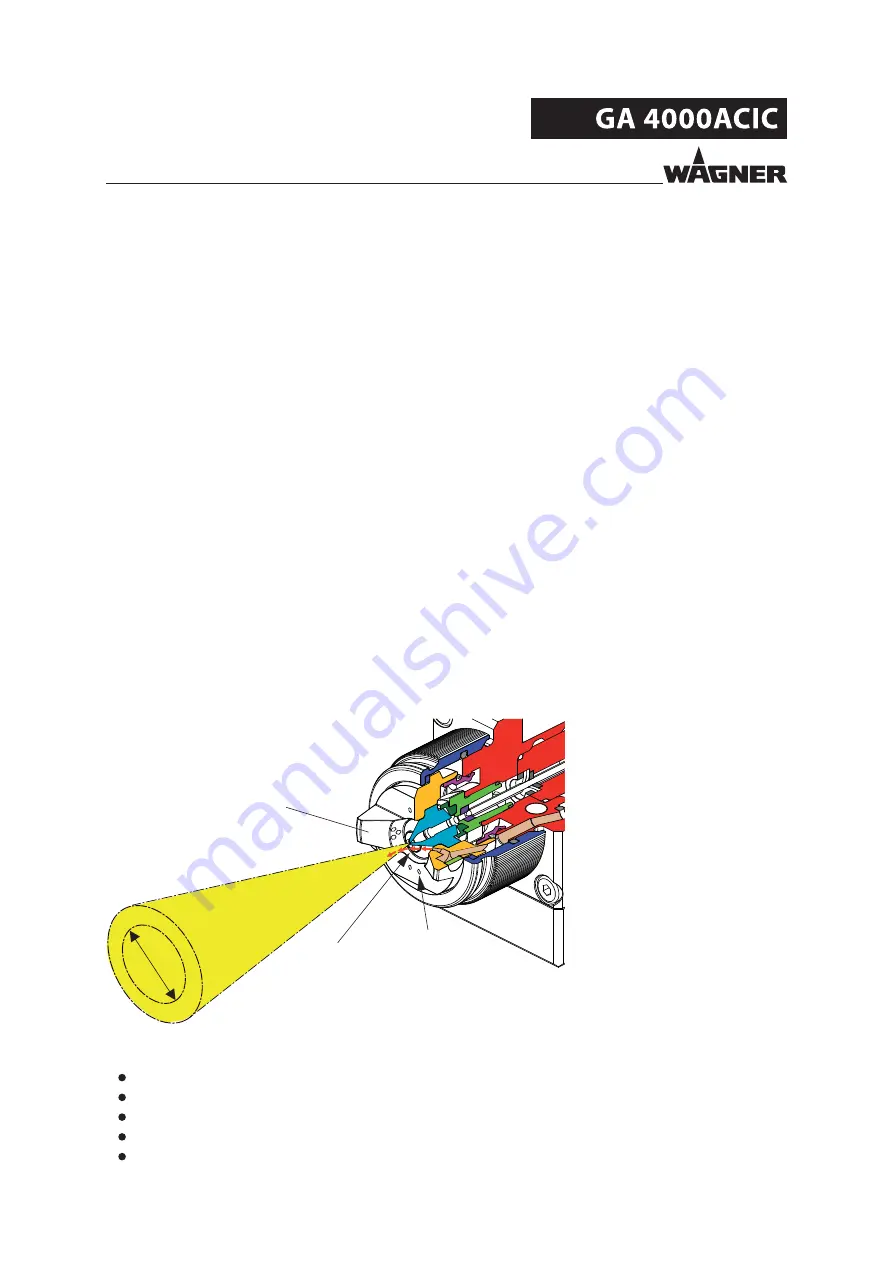

SPRAYING PROCESS

With the AirCoat fl at jet process the spray product is normally atomized at a pressure of

3-12 MPa; 30-120 bar; 435-1740 psi. A soft, fl at spray is achieved with help of the atomizing

air, which has a pressure of 0.05-0.25 MPa; 0.5-2.5 bar; 7.2-36 psi. This eliminates most

overlapping problems in the peripheral zones. The shaping air allows the width of the

spray jet to be increased or decreased.

Advantages:

Large application volume.

Low fogging tendency.

Good fi nish.

High viscosity products can easily be applied.

Jet width adjustment.

5.5.1

FLAT AIRCOAT JET SPRAY PROCESS

Variable spray jet width

Air cap

Shaping air

Atomizing air