42

GA 4000ACIC

OPERATING MANUAL

EDITION 06/ 2011

PART NO. DOC2312956

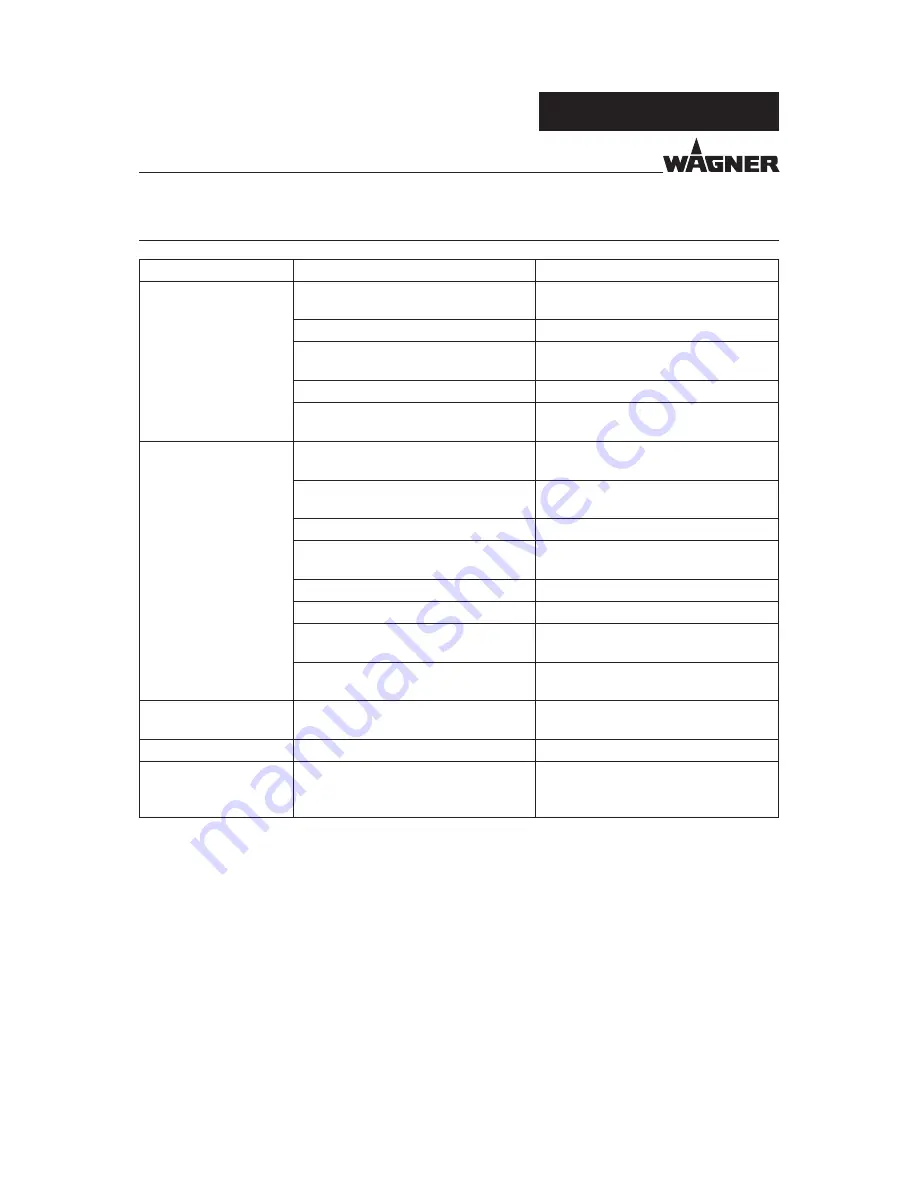

Functional faults

Cause

Remedy

Insuffi cient material

output

Nozzle too small

Select larger nozzle

(see paragraph 8.1)

Material pressure too low

Increase material pressure

Gun fi lter blocked or high pressure

fi lter at pump clogged

Clean or replace fi lter

Nozzle is clogged

Nozzle cleaning (see paragraph 5.4.5)

Valve stem defective

Increase the control air pressure

Replace valve rod

Poor spray pattern

Wrongly adjusted atomizing air

Readjust the atomizing air

(see paragraph 5.4.1)

Nozzle too large

Select smaller nozzle

(see paragraph 8.1)

Material pressure too low

Increase pressure at pump

Material viscosity too high

Thin material in accordance with the

manufacturer‘s instructions

Partial nozzle blockage

Nozzle cleaning (see paragraph 5.4.5)

Wrongly adjusted shaping air

Readjust shaping air

Air cap faulty

(blocked holes, damaged seal)

Clean or replace air cap

Wrong air cap type

Replace as required air cap

(high viscosity/ low viscosity)

Air valve leaks/ Air-

leakage

Air valve seals damaged

Replace air valve seals

(see paragraph 6.3)

Packing leaks

Packings worn

Insert a new packing

Spray gun will not shut-

off correctly / Material

valve leaks

Worn valve seat / valve ball

Replace parts

7

TROUBLE SHOOTING AND SOLUTION