35

VERSION 05/2018

ORDER NUMBER DOC 2312956

GA 4000ACIC

6.8

COMMISSIONING

6.8.1 PREPARATION BEFORE COMMISSIONING

NOTICE

Impurities in the spraying system!

Spray gun blockage.

Flush the spray gun and paint supply with a suitable flushing agent before

commissioning.

6.8.2 COMMISSIONING

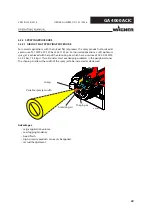

1. Mount spray gun to reciprocator.

B_03071

X

2. Connect product hoses (supply and return flow) to spray gun and product supply

system.

3. Fit nozzle on nozzle seal. Fit air cap over nozzle.

Note the flattened parts (X) on the nozzle and in the air cap.

Fit the union nut and tighten by hand.

4. Connect control air hose and atomizing air hose to spray gun and to oil-free, dry air

supply.

5. Visually check the permissible pressures for all the system components.

6. Make sure that the device and all other conductive parts within the work area are

grounded.

7. Set operating pressure to 100 MPa; 10 bar; 1,450 psi and use a suitable medium to

check no connections are leaking.

8. Relieve the pressure from the spray gun and device.

6.8.3 VERIFYING A SAFE OPERATIONAL CONDITION

A skilled person must check to ensure that the device is in a reliable state after it is

installed and commissioned.

This includes:

– Carry out safety checks in accordance with Chapter

.

Summary of Contents for GA 4000ACIC-S

Page 1: ...Version 05 2018 GA 4000ACIC S GA 4000ACIC R AirCoat Automatic spray gun II 2G X B_06647...

Page 2: ......

Page 66: ......

Page 67: ......