56

GA 5000EA

B_05752

1

4

5

12

6

1

8

AR 5000

3

2

10

7

9

EARV 5000

11

OPERATING MANUAL

VERSION 09/2016

ORDER NUMBER DOC2360924

7.3.5

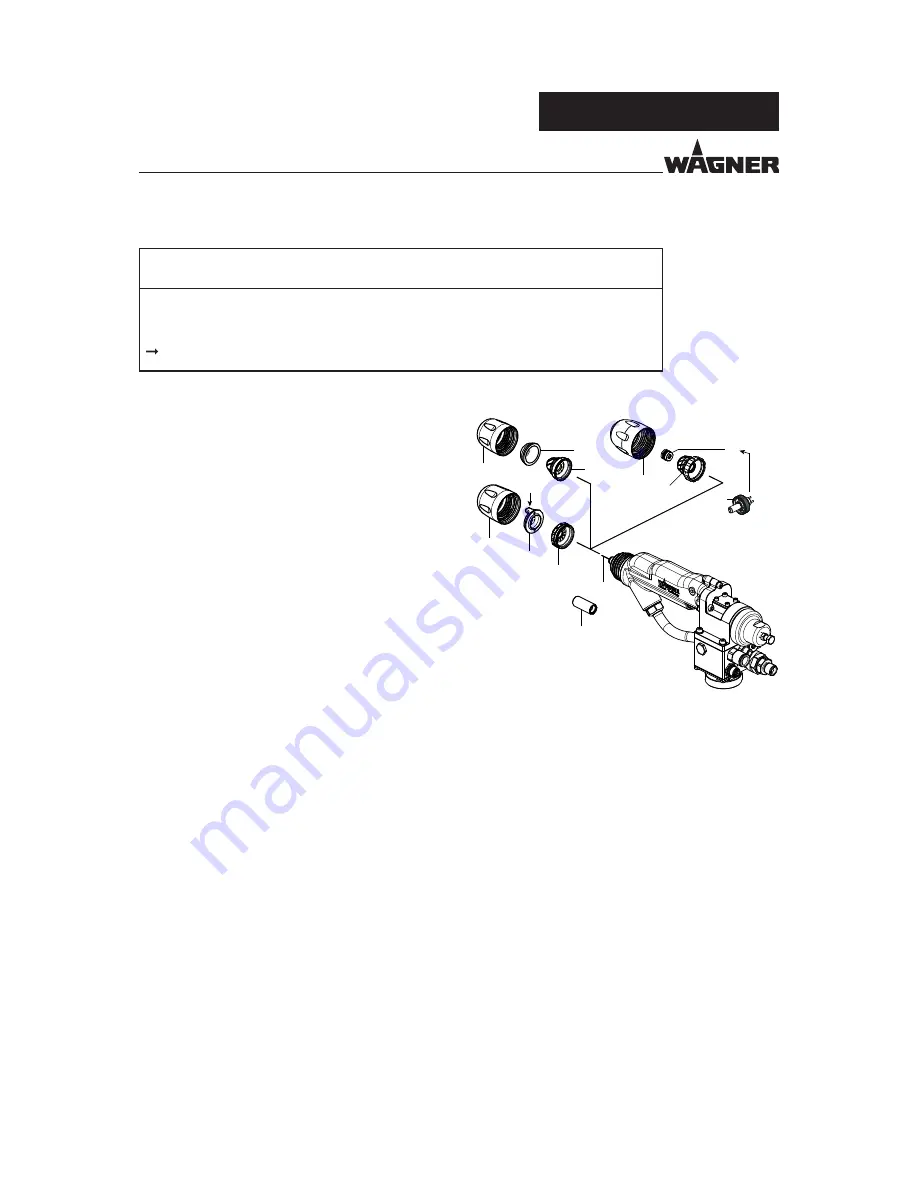

CHANGING FROM AIR ROUND JET TO AIR FLAT JET

Defective electrode!

Material damage due to functional faults.

Do not damage the electrode.

NOTICE

Dismount the nozzle

Flat jet

1. Unscrew the union nut (1) by hand.

2. Remove AF 5000 air cap (4).

3. Unscrew and remove AF 5000 fl at jet nozzle (5) by hand.

4. Clean the spray gun front carefully with damp cloth. Pay attention to the electrode (11).

Use protective cap (12).

AR 5000 – round jet

1. Unscrew the union nut (1) by hand.

2. Remove AR 5000 air cap (2). Unscrew AR 5000 nozzle (3) by hand and remove it.

3. Clean the spray gun front carefully with damp cloth. Pay attention to the electrode (11).

Use protective cap (12).

EARV 5000 – round jet

1. Unscrew the EARV union nut (7) by hand.

2. Unscrew and remove EARV nozzle (8) by hand.

3. Unscrew nozzle insert (9) from nozzle (8) using air nozzle spanner (10).

4. Clean the spray gun front carefully with damp cloth. Pay attention to the electrode (11).

Use protective cap (12).

Flush spray gun:

1.

Switch off high voltage at the control unit.

2.

Turn compressed air regulator for shaping and

atomizing air on the EPG 5000 to "0".

3.

Close the compressed air supply on the

material side upon the product pressure

generator.

4.

Relieve the pressure of gun and system, e.g., by

switching on gun without high voltage.

5.

Fill fl ushing agent and adjust pressure.

6.

Thoroughly fl ush out the spray gun.

7.

Relieve the pressure on the gun and the system.

Summary of Contents for GA 5000EAEC

Page 2: ......

Page 106: ...106 GA 5000EA OPERATING MANUAL VERSION 09 2016 ORDER NUMBER DOC2360924...

Page 107: ......