Specifications

Maximum air input pressure ............145 PSI (1 MPa)

Maximum working pressure .............3600 PSI (25 MPa)

Material quantity .............................according to tip

Air connector ...................................NPSM 1/4"

Material connector ...........................NPSM 1/4"

Filter .................................................100 mesh

Length ..............................................8.5” (216 mm)

Height...............................................9.8” (250 mm)

Weight ..............................................1 lb. (420 g)

Introduction

In the air assisted/airless spraying process, the spraying

material is atomized under pressure at 400 – 2800 PSI (3 – 19

MPa). The atomizing air at 7 – 32 PSI (0 – 0.22 MPa)

produces a soft spray jet that eliminates problems of overlaps

in the boundary zone. The soft spray jet prevents the spraying

material from rebounding to the gun. The form air reduces or

increases the spray jet width, depending on the adjustment of

the air adjustment knob. Due to the cleaning-friendly design of

the tip and the lack of air holes near the material outlet, the tip

is virtually self-cleaning.

When the trigger of the gun is pulled, the air valve opens

allowing atomizing and fan jet air to flow up to the tip. The

material valve opens only when the trigger is pulled to its

fullest extent.

The amount of air for the spray jet width is adjusted using the

air adjustment knob. The spray gun is locked off by turning

the gun lock nut clockwise (when looking from the back of the

gun) until it stops. This closes the material valve in the gun.

The air input should be adjusted at the source to

approximately 0 – 32 PSI (0 – 0.22 MPa).

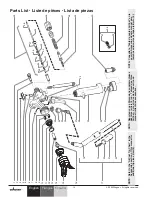

Gun Body

Tip

Guard

Trigger

Material Tube

and Filter

Material Inlet Fitting

Air

Adjustment

Knob

Air

Inlet

Fitting

Gun

Lock

Nut

Atomized Material

Atomizing Air

Form Air

Advantages of the adjustable air assisted/airless process:

• high coverage capacity

• low fogging tendency

• fine finish

• high viscosity materials applied without problems

• higher tool-life of the Brilliant-tip

• adjustability of spray jet width

Materials that can be sprayed using this gun include:

• Water, oil, and solvent based primers and topcoats

• 2K finishing enamels and primers

• Release agents

Operation

Use the following procedure to setup and spray with the spray

gun.

1. Lock the gun by turning the gun lock nut clockwise (when

looking from the back of the gun) until it stops. This

closes the material valve in the gun.

2. Unscrew the tip guard and remove the air cap.

3. Insert the AirCoat tip into the inlet seal sleeve.

4. Place the air cap on the tip. Make sure that the air cap

pins are aligned with the slots on the tip

5. Set the desired spraying plane with the horns of the air

cap and replace the tip guard.

6. Set up the spray unit (refer to the spray unit’s Owner’s

Manual).

7. Connect the material hose from the spray unit to the

material inlet fitting on the gun.

8. Connect the air hose from the spray unit to the air inlet

fitting on the gun.

9. Start up the spray unit (refer to the spray unit’s Owner’s

Manual).

10. Adjust the material pressure at the pump to approximately

400 PSI (3 MPa). Pull the trigger and increase the pump

pressure until the spray pattern is acceptable. Open the

atomizing air at the external air regulator and adjust the

air pressure to the best spray pattern (to a maximum of 32

PSI (0.22 MPa)) . The form air may be adjusted using the

air adjustment knob to the required spray jet width.

Do not turn the air adjustment knob using pliers. Over-

tightening and damage to the gun may occur.

CAUTION

Inlet Seal Sleeve

Air Cap

Tip

Tip Guard

© Wagner. All rights reserved.

3

English

R