Cleanup

• Release system and spray gun pressure before

cleaning or performing maintenance on the gun.

• Use only the cleaning solvent recommended by the

material manufacturer.

• Never spray into an enclosed vessel (this will create

an explosive gas / air mixture).

Daily cleaning

1. Flush out the spray gun material tube thoroughly with the

appropriate solvent.

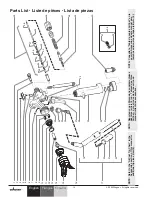

2. Unscrew the tip guard and remove the air cap. Take out

the tip and immerse in the appropriate solvent until all

traces of material are dissolved. Remove the tip and put

into the appropriate solvent for 1 to 2 days until all

material residues are gone.

4. Clean the spray gun body using a brush.

Hold spray gun downward or horizontal while cleaning the

spray gun. Cleaning solvent must not be allowed to enter

the air channels as this will cause swelling of the O-rings.

Maintenance

Adjusting the Needle Packing

If material begins leaking at the valve rod, flush the gun and

carefully tighten the packing screw using the gun spanner that

came with this gun.

CAUTION

NOTE: Handle the tip with care. Do not clean it with

sharp metal objects. Use tip cleaning brush

(P/N 9997001) only. If necessary, use

corresponding tip cleaning needle (P/N

8612001, set of 12) for cleaning tip.

Air channels behind

distributor ring

Air Cap

Tip

Tip Guard

NOTE: When using two component materials more

frequent flushing may be required.

NOTE: Do not immerse the spray gun in solvent.

WARNING

4

© Wagner. All rights reserved.

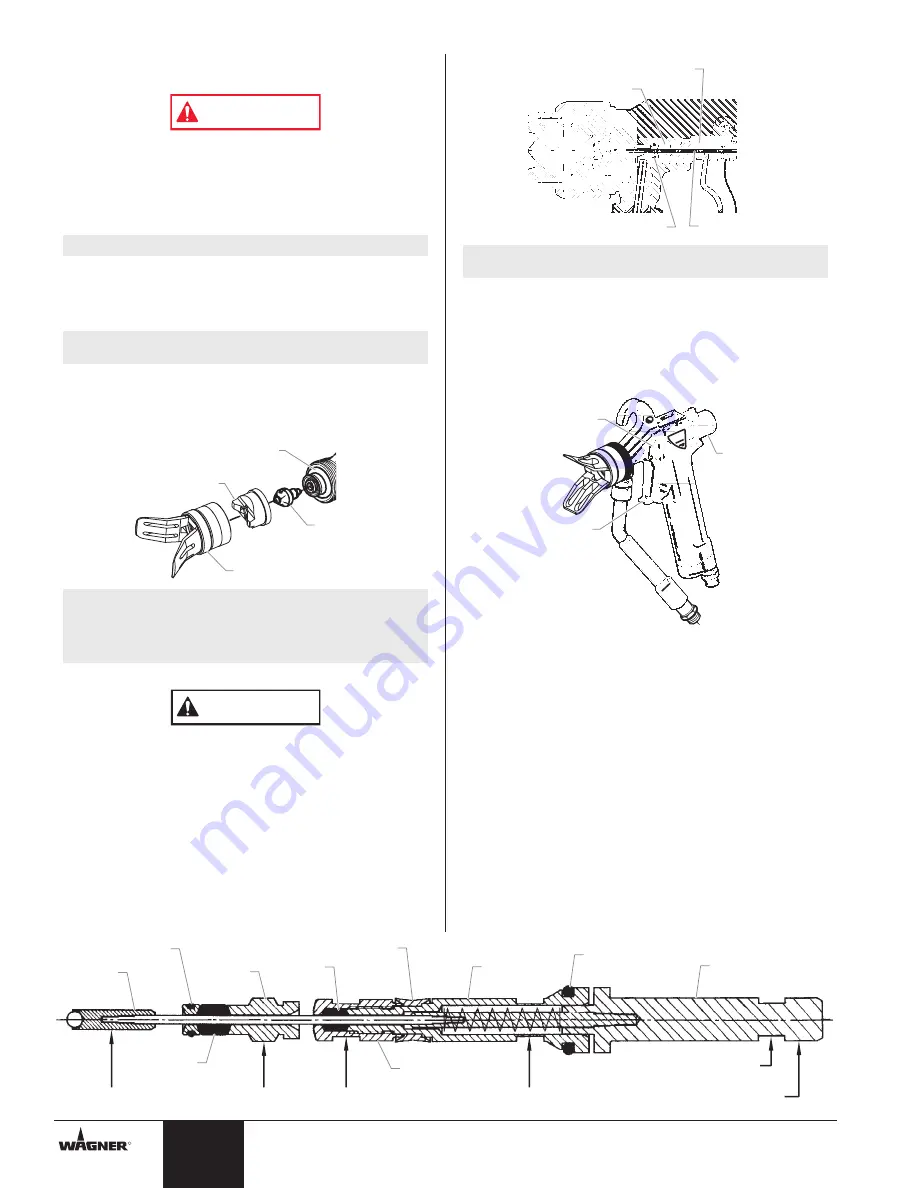

Replacing the Valve Rod Seals

Refer to the valve rod complete illustration at the bottom of the

page.

1. Pull the trigger and unscrew the gun lock nut. Remove

the compression spring.

2. Remove the flat-head screw and take off the trigger.

3. Unscrew the packing screw from the sealing sleeve.

4. Carefully withdraw the complete valve rod from the back

of the gun.

5. Holding the valve rod mounting with the gun spanner,

unscrew the valve ball holder using pliers.

6. Remove the components from the needle.

7. Remove the compression ring and needle packing.

Repairing Air Valve Seals

1. Holding the valve push-rod with the universal spanner,

unscrew the push-rod cap.

2. Change compression ring (with O-ring), needle packing,

rear seal, and, if necessary, the push-rod seal and air

valve seal of the air valve

3. Reassemble in reversed order

4. The trigger must be pulled before replacing the gun lock

nut and the compression spring. Screw on the nut until a

noticeable resistance is felt at the trigger. Release the

trigger. The lever travel is now correctly set for air and

material release.

Trigger

Flat-Head

Screw

Gun

Lock

Nut

NOTE: If leaking continues, replace the needle

packing and the o-ring.

Needle Packing

Packing Screw

O-Ring

Valve Rod

English

R

Use pliers

here

Unscrew

here

Unscrew

here

Hold with

spanner here

Hold with

spanner here

Hold to remove

valve rod here

Valve Ball

Holder

Packing

Screw

Rear

Seal

Push-Rod

Seal

Air Valve

Seal

Valve

Push-Rod

Valve Rod

Mounting

Push-Rod

Cap

Needle

Packing

Compression Ring