23

GM 4600AC

B_02261

x

A

B

C

D

B_02676

OPERATING MANUAL

EDITION 02/2008

Part No. DOC394861

5.4.4

CLEANING AIRCOAT NOZZLE

For disassembly and assembly of AirCoat nozzles see chapter 5.4.3.

The AirCoat nozzle (C) can be placed into a cleaning solvent which has been recommend-

ed by the paint manufacturer.

5.4.5

ELIMINATE NOZZLE CLOGGING

1. Relieve spray gun and unit pressure.

2. Secure gun with trigger safety catch.

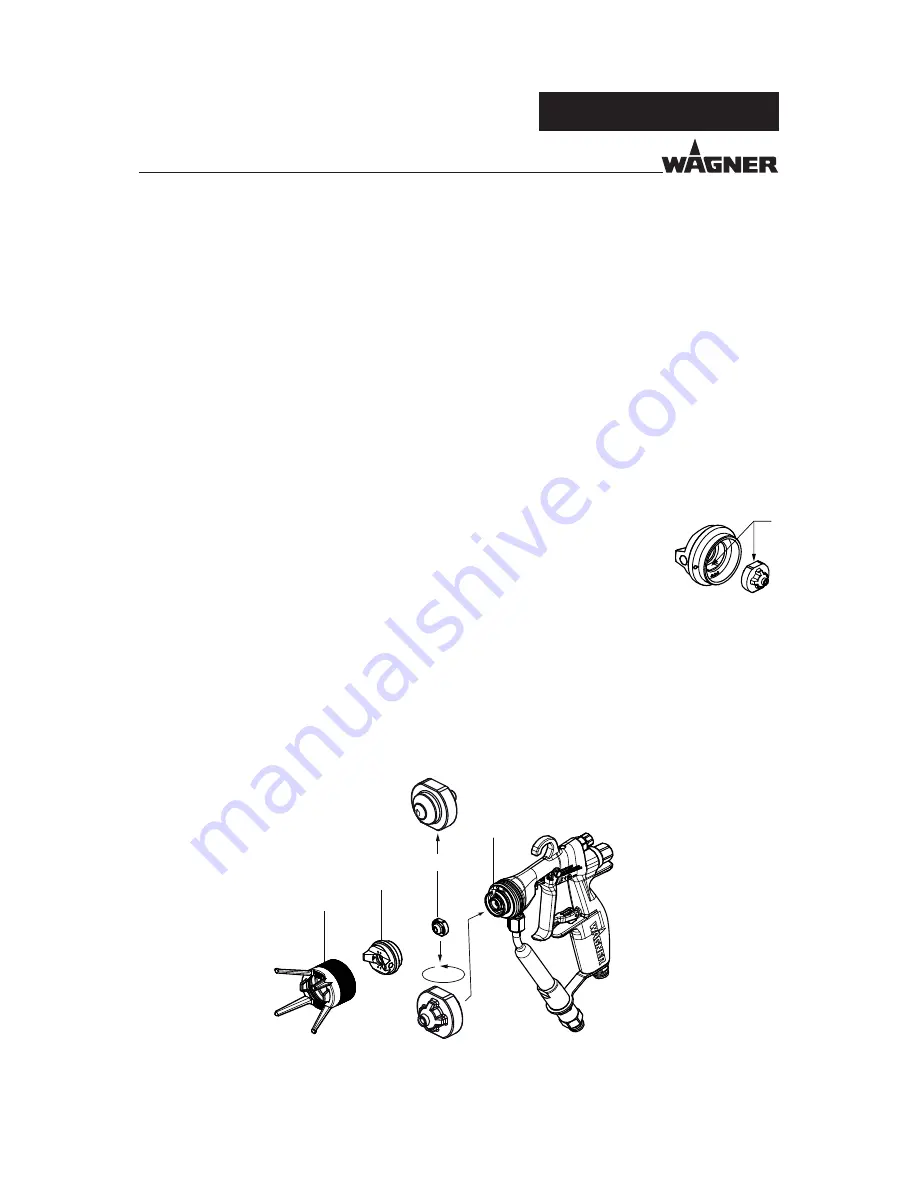

3. Unscrew the union nut with nozzle guard (A).

4. Remove air cap (B).

5. Pull out the clogged nozzle (C) from the air cap (B), reverse it and replace it into nozzle

seal (D).

6. Fit the air cap (B) over the nozzle (C), ensuring that the location fl ats (X) are in line.

7. Fit the union nut with nozzle guard (A) over the air cap (B) onto the spray gun and

tighten by hand.

8. Switch the material pressure back on.

9. Turn the safety catch to the spraying position and briefl y pull trigger.

10. When the blockage has been fl ushed out secure the gun with safety catch.

11. Relieve spray gun and unit pressure.

12. Unscrew the union nut with nozzle guard (A).

13. Remove air cap (B) and reverse nozzle (C) again. Clean nozzle and replace on the nozzle

seal (D) in spray position.

14. Fit the air cap (B) over the nozzle (C), ensuring that the location fl ats (X) are in line.

15. Fit the union nut with nozzle guard (A) over the air cap (B) onto the spray gun and

tighten by hand.

16. Switch the material pressure and the air pressure back on.

Nozzle in „spray“ position

Nozzle in „cleaning“ position