37

10.5 REPLACING THE NOZZLE SEAL

NOTICE

Defective nozzle seal!

Product sprays into the air cap next to the nozzle.

Do not clean the nozzle seal with sharp-edged objects.

Replace the nozzle seal if the sealing surface is damaged.

1. Relieve the pressure of the spray gun and device

in accordance with Chapter

16

17

14

13

36

33

B_02389

2. Decommission and clean in accordance with

Chapter

3. Secure the spray gun with the trigger locking

device.

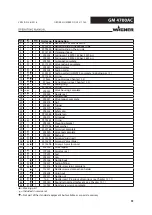

4. Unscrew the union nut with nozzle guard (33).

5. Remove the air cap (36) together with the nozzle

(13).

6. Carefully release the nozzle seal (17) using a

screwdriver.

7. Attach the new nozzle seal to the valve housing (16).

8. Continue assembly in the reverse order.

10.6 REPLACING THE "AIR" SEALING RING

NOTICE

Shaping air and atomizer air not separate!

Poor spray pattern.

Spray jet cannot be adjusted.

Handle the sealing ring (14) with care.

1. Relieve the pressure of the spray gun and device in

accordance with Chapter

.

4

1

3

2

14(F)

13

36

33

B_02390

2. Decommission and clean in accordance with Chapter

.

3. Secure the spray gun with the trigger locking device.

4. Unscrew the union nut with nozzle guard (33).

5. Remove the air cap (36) together with the nozzle (13).

6. Remove the defective sealing ring (14/F) with the

help of pipe tongs or with a large screwdriver.

Assembly:

7. Plug the new sealing ring (14) onto the air cap (36).

8. Place air cap in body of gun together with sealing

ring (14).

9. Attach the union nut (33) and screw it in until the

sealing ring snaps into place in the mounting groove

(audible snap).

10. Demount the union nut (33) and air cap (36) and

complete the spray gun in accordance with Chapter

VERSION 06/2018

ORDER NUMBER DOC2311730

Summary of Contents for GM 4700AC

Page 1: ...AirCoat Manual Gun for Flat and Round Jet Nozzles Version 06 2018 B_02376...

Page 2: ......

Page 48: ...48...