41

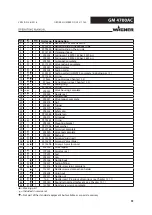

11 FUNCTION TEST AFTER REPAIR WORK

After all repair work, the spray gun must be checked for safe condition before

recommissioning. The necessary scope of inspection and testing depends on the repair

carried out and must be documented by the repair personnel.

Assembly inspection

Activity

Means

1. Leak test

– Connect 1 bar; 0.1 MPa; 14.50 psi and 8 bar; 0.8 MPa; 116 psi air pressure

to the air connection and product connection.

Air connection 1 bar / 8

bar

Place the spray gun completely into the water bath and check all sealing

points with 1 bar; 0.1 MPa; 14.50 psi and 8 bar; 0.8 MPa; 116 psi for leaks.

At 8 bar; 0.8 MPa; 116 psi bar, the gun must be completely sealed.

At 1 bar; 0.1 MPa; 14.50 psi, a slight leak can be tolerated: 5 air bubbles

per minute.

Water bath

Injection and Final Inspection

Activity

Means

2. Trigger lever function test

– The trigger lever must be pulled as far as it will go.

Manual inspection

Make sure that the trigger lever can move slightly in its rest position.

– Put the trigger lever locking device into the locking position, configure

the air product pressure, and pull the trigger lever.

Neither air nor product may leak or escape.

– Check that the trigger lever locking device is not reset by the trigger

lever when pulling in the locking position.

3. Leak test

– Connect the gun, slowly increase the product pressure in increments

using a suitable medium until the maximum pressure (250 bar, 25 MPa;

3625 psi or 160 bar, 16 MPa; 2320 psi) specified on the spring cap is

reached.

Visual inspection

– Trigger and flush the spray gun multiple times.

The 160 bar variant is

inspected at 160 bar.

– Check the following:

- Is the product connection sealed when the gun is closed?

- Is the product valve sealed?

- Is there no product discharge at the valve rod seal?

250 bar or 160 bar product

connection

Atomizing air 3 bar

Size 7 open-end wrench

for the sealing screw

If product leaks, tighten the sealing screw:

The sealing screw on the valve rod must be tightened.

Tighten the sealing screw with the open-end wrench if necessary.

(In doing so, it is important to make sure that the valve rod still runs

smoothly and the gun closes reliably).

VERSION 06/2018

ORDER NUMBER DOC2311730

Summary of Contents for GM 4700AC

Page 1: ...AirCoat Manual Gun for Flat and Round Jet Nozzles Version 06 2018 B_02376...

Page 2: ......

Page 48: ...48...