73

6

7

B_03205

SW3

0.8 Nm

SW21

SW19

B_04380

SW22

SW19

SW19

2.5 Nm

2

5

5

25

2

2

OPERATING MANUAL

EDITION 05/2015

ORDER NUMBER DOC2319150

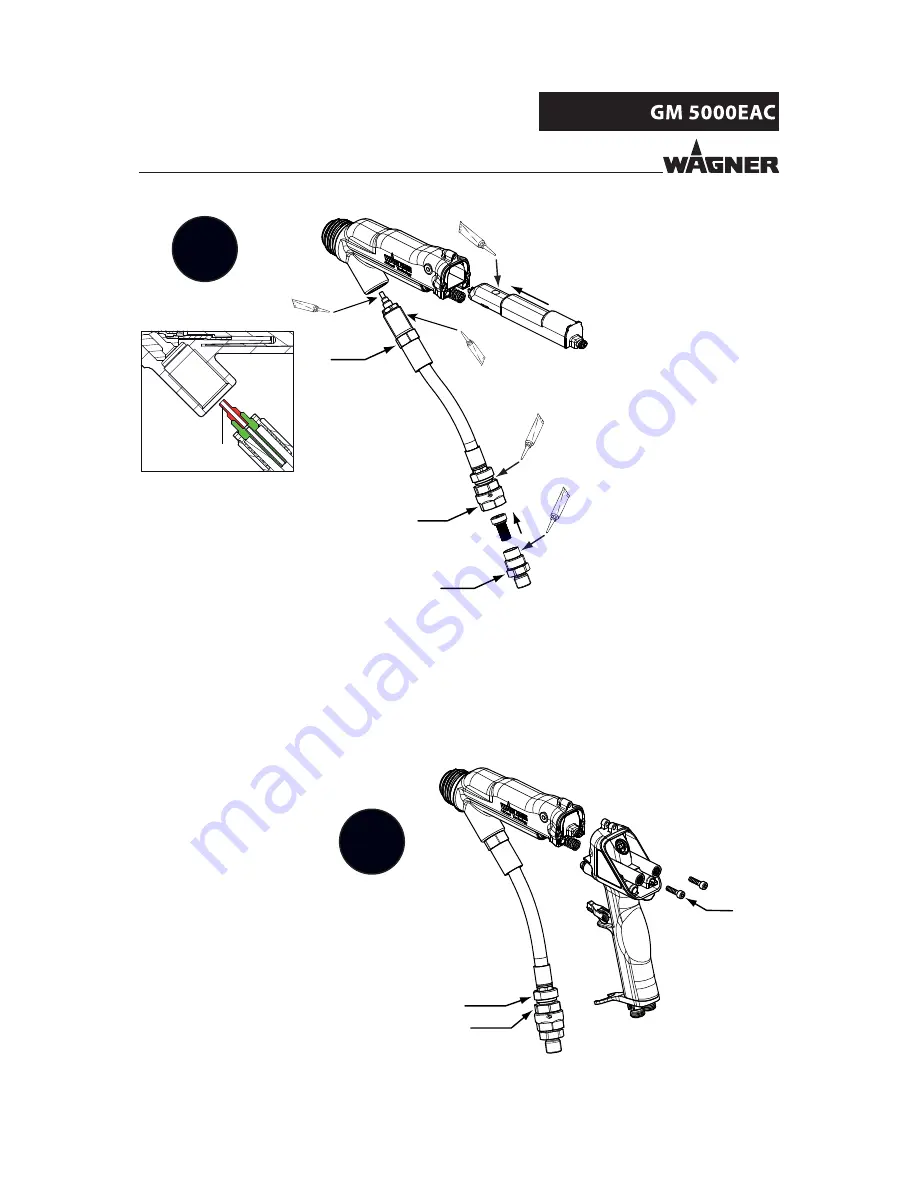

Clean and degrease the

inside of the adapter and

the cascade, then grease

the cascade surface with

Vaseline.

Fitting (25)

Before assembling the product hose,

check that no fi tting (25) is in the gun

adapter!

Check the fi tting for damage and replace

if necessary (Order No. 2338853).

Ensure that the spring is inserted in the

adapter.

Ensure that the fl at gasket is inserted in the

handle.

Summary of Contents for GM 50000EAC

Page 2: ......

Page 30: ...30 OPERATING MANUAL EDITION 05 2015 ORDER NUMBER DOC2319150...

Page 53: ...53 OPERATING MANUAL EDITION 05 2015 ORDER NUMBER DOC2319150...

Page 62: ...62 OPERATING MANUAL EDITION 05 2015 ORDER NUMBER DOC2319150...

Page 103: ...103 OPERATING MANUAL EDITION 05 2015 ORDER NUMBER DOC2319150...

Page 104: ...104 OPERATING MANUAL EDITION 05 2015 ORDER NUMBER DOC2319150...

Page 106: ...106 OPERATING MANUAL EDITION 05 2015 ORDER NUMBER DOC2319150...

Page 107: ......