74

GM 5000EA

B_03260

OPERATING MANUAL

EDITION 04/2016

ORDER NUMBER DOC2344499

11.2

AIR TEST

11.3

PRODUCT PRESSURE TEST

Connect test or air hose to spray gun.

The following air tests are to be carried out twice each:

- at 0.1 MPa; 1 bar; 14.5 psi

- at 0.8 MPa; 8 bar; 116 psi

Checking the air valve

The air valve must switch on and off correctly.

Air seal

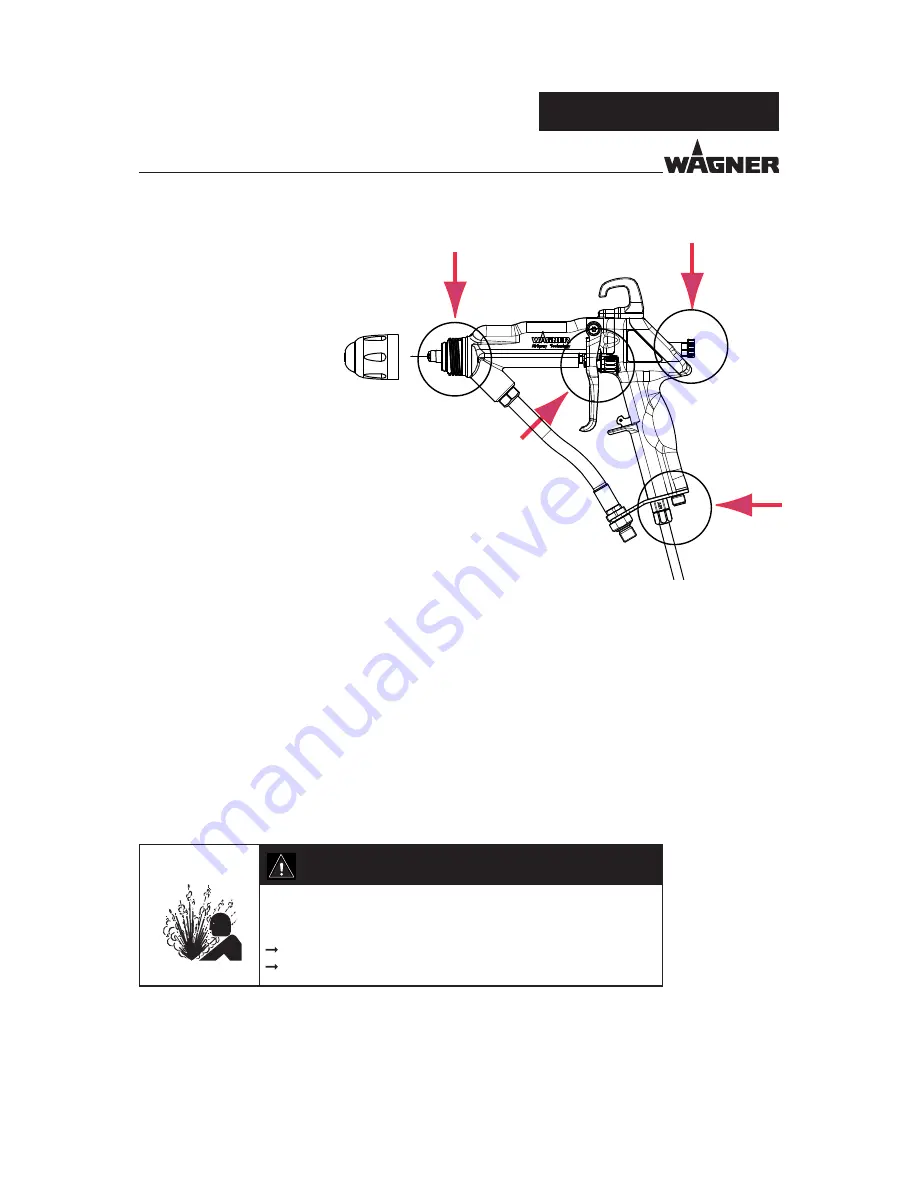

Without activating the trigger, test for air seal at the points

marked in the illustration.

Connect low-pressure hose to the spray gun.

Spray gun with suitable medium (e.g., fl ushing agent or Marcol 52) and a maximum

pressure of 0.8 MPa; 8 bar; 116 psi. Increase the pressure gradually while doing so.

Observe the following gun components:

Product connection, nozzle body, product valve (no post-spraying).

Exploding gas / air mixture!

Danger to life from fl ying parts and burns.

Never spray into a closed tank.

Ground the tank.

DANGER

11.4

TEST OF SPRAY PATTERN

Check spray pattern in accordance with Chapter 7.3.2.