9

GM 5000EAC

.

OPERATING MANUAL

EDITION 03/2012

PART NUMBER DOC 2319150

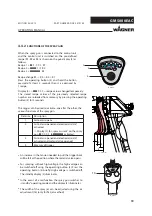

2.2.4

CLEANING

2.2.5

HANDLING HAZARDOUS LIQUIDS, VARNISHES AND PAINTS

When preparing or working with paint and when cleaning the unit, follow the working

instructions of the manufacturer of the paints, solvents and cleaning agents being

used.

Take the specified protective measures, in particular wear safety goggles, protective

clothing and gloves, as well as hand protection cream if necessary.

Use a mask or breathing apparatus if necessary.

For sufficient health and environmental safety: Operate the unit in a spray booth or on

a spraying wall with the ventilation (extraction) switched on.

Wear suitable protective clothing when working with hot materials.

De-energize the unit electrically.

Disconnect the pneumatic supply line.

Relieve the pressure from the unit.

Ensure that the flash point of the cleaning agent is at least 15K above the ambient tem-

perature. Otherwise, the cleaning works shall be carried out at forced ventilated clea-

ning place.

To clean, use only solvent-soaked cloths and brushes. The cleaning process mustn´t

damage parts of the spray gun, it mustn´t be an abrasive procedure.

Parts of spray gun mustn´t submerged or soaked into solvent.

Non-ignitable cleaning liquids shall be preferred.

A suitable solvent for cleaning the spray gun depends on the part of the gun and on the

material that needs to be removed. It´s recommended to use only non-polar solvents

to prevent a conductive residue on critical components. If it´s necessary to use polar

solvents to clean the spray gun components, all residue must be removed by using a

nonconductive non-polar solvent.

All electrical components cannot be cleaned or soaked in any solvents.

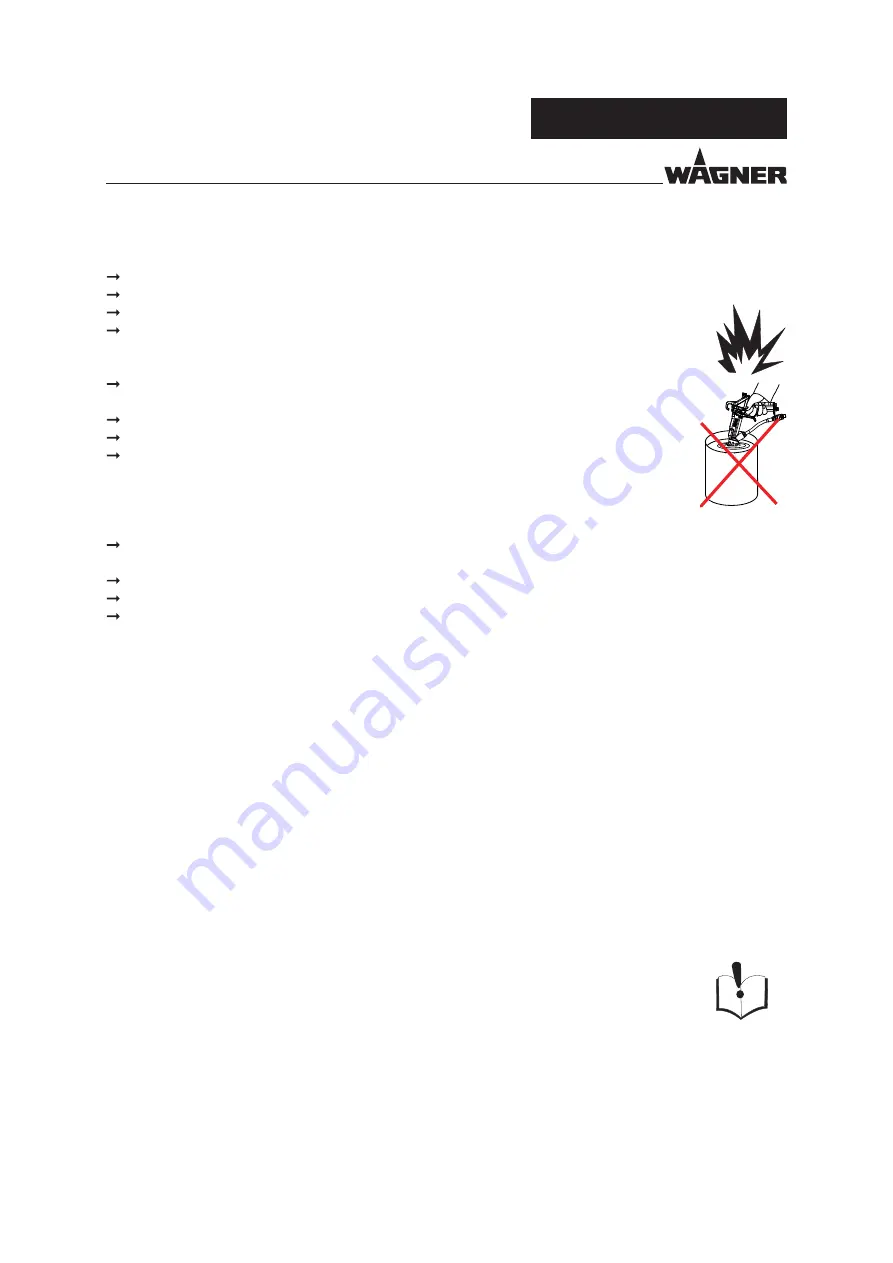

An explosive gas/air mixture forms in closed containers.

When cleaning units with solvents, never spray into a closed container.

For cleaning liquids only electrically leading containers may be used.

The containers must be earthed.