19

VM 500

B_03234

R max < 1 M

Ω

OPERATING MANUAL

EDITION 03/2012

PART NUMBER DOC 2318724

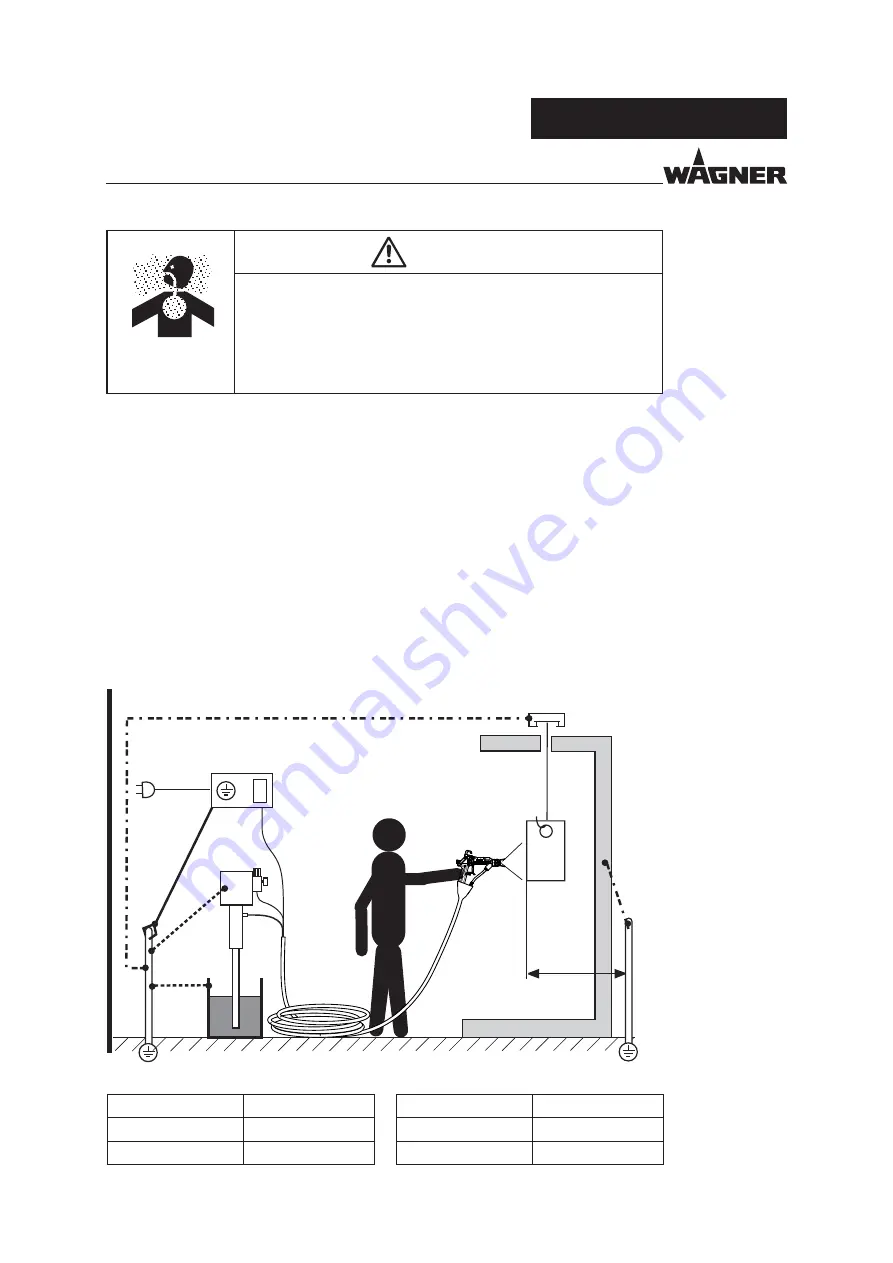

Earthing scheme (example)

Conveyor

Control unit

Earthing

cable

Spraying stand

Floor, derivable

Work piece

Material

supply

Paint container

The imperfect earthing of a work piece will result in:

•

Very poor wrap-around.

•

Uneven coating thickness.

•

Back spraying to the spray gun (contamination) and coater.

The prerequisites for perfect earthing and coating are:

•

Clean work piece suspension.

•

Earthing of spray booth, conveyor system and suspension on the building side in

accordance with the operating instruction or the manufacturer‘s information.

•

Earthing of all conductive parts within the working area.

•

The earthing resistance of the work piece may not exceed 1 M

(Mega Ohm).

Note:

Resistance to earth measured with 500 V or 1000 V.

•

Connect the control unit to the mains system earth.

Note for the sprayer

The work shoes and if used

the gloves must be

derivable.

WARNING

Heavy paint mist if earthing is insufficient!

Risk of poisoning

Insufficient paint application quality

Earth all unit components.

Earth the workpieces being painted.

SIHI_0003_GB

Minimum cable cross-section

Control unit

4 mm² (AWG 12)

Material supply

4 mm² (AWG 12)

Paint container

4 mm² (AWG 12)

Conveyor

16 mm² (AWG 6)

Booth

16 mm² (AWG 6)

Spraying stand

16 mm² (AWG 6)

Summary of Contents for GM5000

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ...Prime Spray Valve ASSY 0555901________...

Page 20: ......

Page 21: ......

Page 23: ......

Page 52: ......

Page 55: ......

Page 121: ...68 GM 5000EAC OPERATING MANUAL EDITION 03 2012 PART NUMBER DOC 2319150...

Page 122: ...69 GM 5000EAC OPERATING MANUAL EDITION 03 2012 PART NUMBER DOC 2319150...

Page 124: ......