HC 35 E • HC 45 E • HC 55 E

49

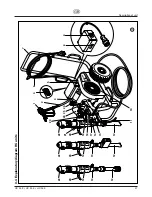

g

7.

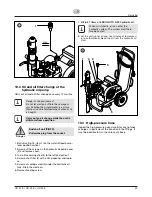

Fill in 4.7 liters of ESSO NUTO H 32 hydraulic oil.

8. Let the unit run for at least five minutes at low pressu-

re to automatically bleed the air from the hydraulic sy-

stem.

Servicing

1

min:

max:

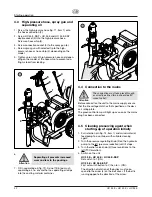

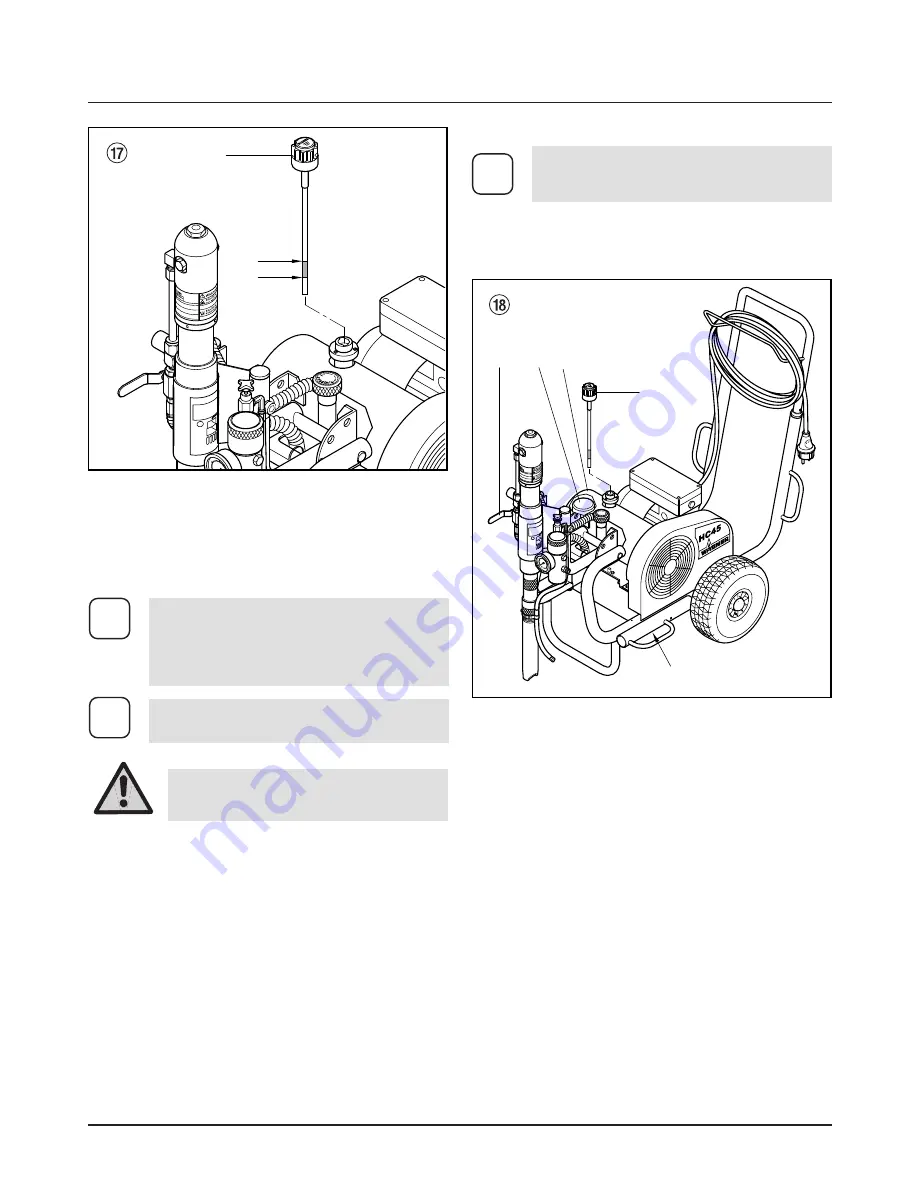

1. Ball valve (fig. 18, item 1) on the material feed pump –

lever position vertical.

2. Screw out the screws on the hydraulic oil pump cover

(2) and remove cover.

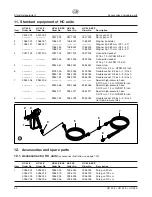

3. Turn oil measuring stick (3) to the left and pull out.

4. Screw out oil filter (4) with a strap spanner and repla-

ce.

5. Screw out sealing screw (5) under the hydraulic oil

tank. Drain the waste oil.

6. Remount sealing screw.

Danger to the environment

Do not let waste oil off into the sewage or

soil. Polluting the ground water is a crime.

Waste oil can be returned when hydraulic oil

is bought.

i

Danger

Switch off unit

A

(OFF).

Pull mains plug from the socket.

10.3 Oil and oil filter change ot the

hydraulic oil pump

Carry out oil and oil filter change once every 12 months.

Carry out an oil change while the unit is

still warm from operation

i

When oil is filled in, air can enter the

hydraulic system. The system must there-

fore be vented

i

1

3

4

2

5

10.4 High-pressure hose

Inspect the high-pressure hose visually for any notches

or bulges, in particular at the transition in the fittings. It

must be possible to turn the union nuts freely.