37

Super Finish 33 PLUS/PRO • Nespray Pro

Earthing and short-circuiting

After ensuring safe isolation from the supply, the conductors and earthing must be connected together with short-circuit-proof

earthing and shorting jumpers. With this measure, the upstream overcurrent protective devices trigger and the system is imme-

diately isolated in the event of inadvertent restoration of power. It should be noted that earthing is carried out fi rst, then short-

circuiting.

Cover or shield any adjacent live parts.

Often inadmissible approach to adjacent live system parts cannot be easily prevented. In such cases these system parts must be

protected against accidental contact by permanent and securely fi tted insulating covers.

1.6

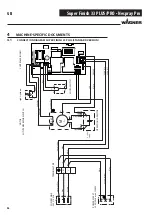

CATEGORISATION OF PROTECTION CLASSES

Legal basis

In electrical engineering, protection classes enable the categorisation and identifi cation of electrical equipment (for example,

devices and installation components) in relation to the existing safety measures for protection against electric shock.

The protection classes are defi ned for all electrical equipment in DIN EN 61140 (VDE 0140-1).

A distinction is made between four protection classes for electrical equipment. Symbols are provided in order to identify equip-

ment with the relevant protection class. These symbols are defi ned in IEC 60417. The use of safety precautions in the diff erent

classes of electrical equipment is described in DIN EN 61140 (VDE 0140-1):2007-03, section 7.

Protection class 0

There is no special protection against electric shock in addition to the basic insulation. Connection to the protective conductor

system is not possible. Appliances with this protection class are not permitted in Germany and Austria. This protection class will

not be included in any international standards in future. There is no symbol for protection class 0.

Protection class I

All electrically conductive housing parts of the equipment are connected to the protective conductor system of the fi xed elec-

trical installation, which is at earth potential. Mobile appliances in protection class I have a plug connector with a protective

conductor contact or an earthing pin plug. These must be executed so that the protective conductor connection is established

as the fi rst connection on plugging in. It must also be ensured that in the event of damage the protective conductor connection

is disconnected last. The connecting cable entry into the appliance must be mechanically strain-relieved

Protection class II

Equipment in protection class II has reinforced or double insulation around live parts, so that no conductive parts can be live

even in fault conditions. This is also referred to as total insulation. Appliances in protection class II do not have a protective con-

ductor contact.

Protection class III

Appliances in protection class III operate with safety extra-low voltage (SELV).

Safety extra-low voltage means voltages that do not exceed 50 V AC (alternating voltage) or 120 V DC (direct voltage). This vol-

tage must be generated by a safety transformer as per DIN VDE 0570-2-6 or EN 61558-2-6 for a mains-operated appliance.

Safety extra-low voltage taken from batteries or accumulators belongs to protection class III without the need for further mea-

sures.

GB