Inlet

fitting

O-ring

Inlet

fitting

O-ring

Inlet

fitting

O-ring

Inlet

fitting

Inlet

valve

Inlet

valve

O-ring

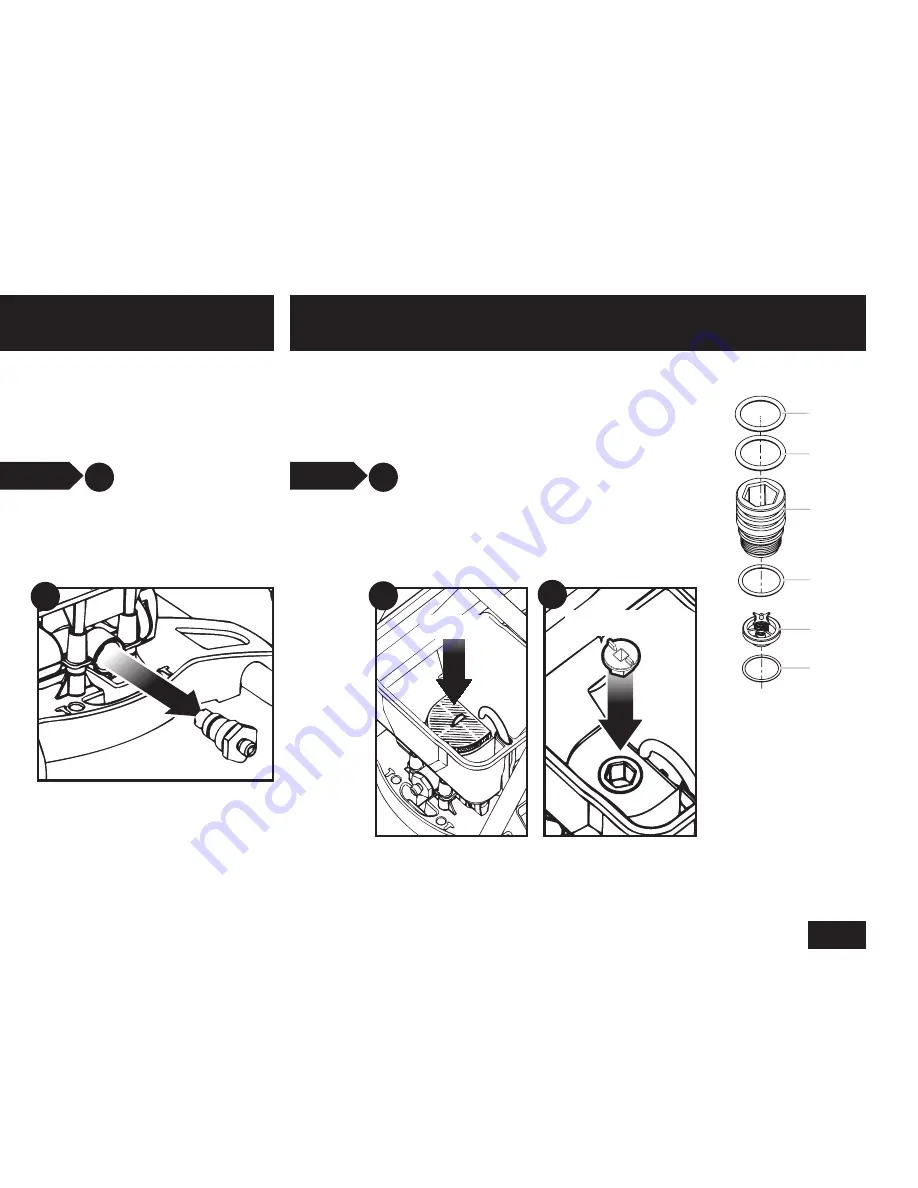

2.

Remove inlet filter from

bottom of hopper

4.

Inspect the three inlet fitting

O-rings and replace if worn. If

not replacing O-rings do not

remove them but clean with

appropriate cleaning solution

based on material being used.

Lubricate with light household oil

5.

Place inlet valve O-ring in

housing and set inlet valve on

top of O-ring

6.

Replace inlet fitting in house

and tighten with inlet valve tool

and ratchet wrench

INLET VALVE TOOL

What you’ll need

•

Wrench

•

Rag

•

Warm, soapy water if using

latex material

•

Mineral spirits for oil based

material

Start

Replacing Outlet Valve

REMOVE

3.

Attach inlet valve tool to

ratchet wrench extension.

Insert inlet valve tool into inlet

fitting. Turn counter-clockwise

and remove from housing

2.

Unscrew outlet valve from outlet valve

housing using wrench

3.

Remove any accumulated material inside

outlet valve housing using appropriate solution

for material being used

4.

Replace with new outlet valve and tighten

with wrench

REMOVE

Cleaning or replacing the inlet valve may be necessary if

spray performance remains poor after following steps in

the Fix Spraying Problems section. Problems with the inlet

valve are usually caused by improper cleaning or storage.

Replacement kits may be ordered by calling the customer

service number found on

page 2

Replacement of the outlet valve may be

necessary if spray performance remains

poor after following steps in the Fix

Spraying Problems section.

Replacement

valves can be ordered by calling the customer

service number found on

page 2

What you’ll need

•

Inlet valve tool

•

Ratchet wrench, extension

•

Household oil

•

Warm, soapy water if using latex material

•

Mineral spirits for oil based material

Cleaning or Replacing Inlet Valve

Start

INLET VALVE

2

1

3

2

1

English

24

Troubleshooting

Troubleshooting

• Replace Outlet Valve