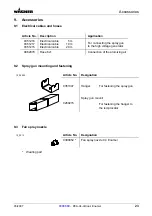

Preparing the spray gun

Caution

The distance of the installed spray guns to each other

must be at least 300 mm

.

•

Fit the spray gun to the hanger and fasten both, for example, to the gun mounting on the

reciprocator.

•

Connect the spray gun to the high voltage generator using the electrical cable

E

.

•

Connect the hose for the powder feed

P

to the spray gun.

•

Connect the hose for the atomizing air

A

to the spray gun.

Hint

Using a Wagner powder injector and a suitable control unit, it is possible to

automatically blow out or purge the angled spray gun each time prior to switch off.

3.3 Grounding

For safety reasons, the

spray gun

must

be properly grounded. This occurs through the gun

mounting.

0203_ .doc

Good grounding of the

workpiece

is also necessary for optimum powder coating.

A poorly grounded workpiece causes:

•

dangerous electric charging of the workpiece

•

back-spray onto spray gun and user

•

uneven coating

•

very bad wrap around

Warning

Sparks between workpiece and conveyor hooks (hangers) can occur if

hooks or other hanger parts are not completely cleaned!

These sparks can cause heavy radio frequency interference.

05/2007

0390860

– PEA-C4-HiCoat- Enamel

11