29

PEA-C4XL-S

1

2

4

3

5

6

P_02338

OPERATING MANUAL

VERSION 03/2014

ORDER NUMBER DOC2345334

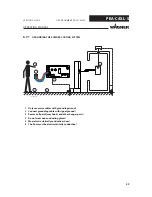

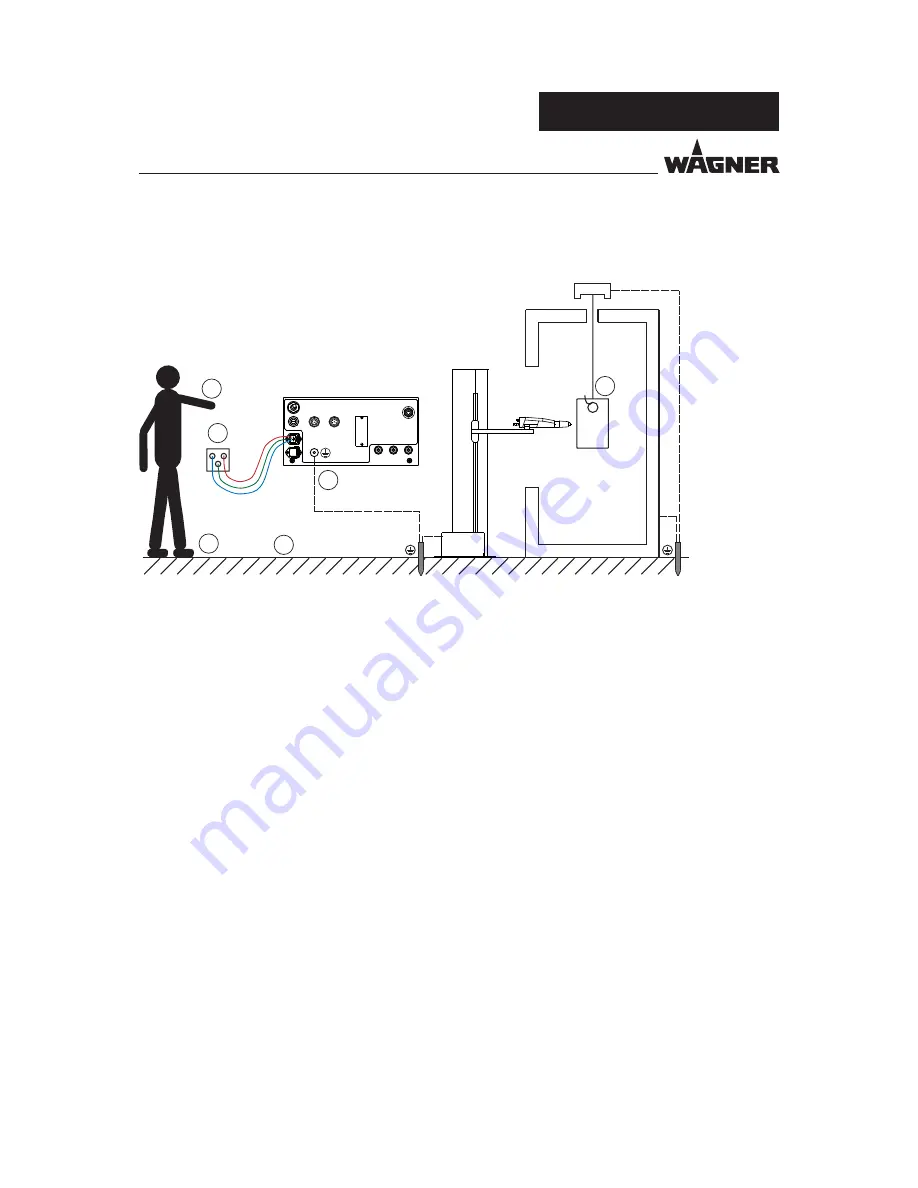

6.7.1

GROUNDING THE POWDER COATING SYSTEM

1

Only use mains cables with grounding strand!

2

Connect grounding cable with signal ground!

3

Remove all paint from hooks and other hanger parts!

4

Do not wear non-conducting gloves!

5

Wear electrostatically conductive shoes!

6

The fl oor must be electrostatically conductive!

Summary of Contents for PEA-C4XL-S

Page 2: ......

Page 24: ...24 PEA C4XL S OPERATING MANUAL VERSION 03 2014 ORDER NUMBER DOC2345334 ...

Page 55: ...55 PEA C4XL S OPERATING MANUAL VERSION 03 2014 ORDER NUMBER DOC2345334 ...

Page 73: ...73 PEA C4XL S OPERATING MANUAL VERSION 03 2014 ORDER NUMBER DOC2345334 ...

Page 74: ...74 PEA C4XL S OPERATING MANUAL VERSION 03 2014 ORDER NUMBER DOC2345334 ...

Page 75: ......