23

PEM-C4-Ergo

.

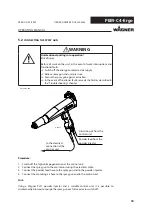

30°

15°

0°

X

X

P_01095

P_01096

OPERATING MANUAL

VERSION 02/2009

ORDER NUMBER DOC2305054

6.3.2

FLUSHING PROCEDURE IN CONJUNCTION WITH EPG 2008/EPG PRIMA CONTROL UNIT

If the spray gun is operated with an EPG 2008/EPG Prima control unit and a PI-P1 powder

injector, proceed as follows:

1. Release the trigger on the spray gun so that the powder feed and high-voltage

generator are switched off.

2. Set the knob for the overall air quantity on the EPG 2008/EPG Prima control unit to

maximum. No more powder will be delivered when switching on again.

3. Press the trigger on the spray gun so that the spray gun is blown free of powder.

4. Switch off the control unit and secure against inadvertent switch on.

5. Disconnect the powder hose from the spray gun.

6. Clear the spray gun using the air gun and clear any residues of powder.

7. Before you commence to connect the powder hose again, all parts carrying powder

must be thoroughly cleaned.

8. The spray gun is ready for use again.

6.4

REPRODUCIBLE SETTING OF THE NOZZLE POSITION

●

For a horizontal powder cloud, the fan

spray nozzle is set where the protective

wedge is in the 0° position.

●

When attaching a round spray nozzle,

we recommend turning the protective

wedge in the 90° position to achieve a

smoother coating (the protective wedge

is now in the vertical position).

It is possible to set it other positions for

special applications.

On the nozzle body and electrode

holders there are X markings. In 15° steps, the

position can be changed if necessary and

reproducibly.

The outer nut has to be removed for exact

positioning.

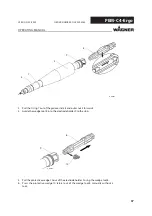

An adjustment tool is provided for the fan

spray nozzle.

It permits turning the fan spray nozzle

without damaging the electrodes and

without removing the outer nut.

The outer nut only has to be slackened.