7

PEM-C4-Ergo

.

OPERATING MANUAL

VERSION 02/2009

ORDER NUMBER DOC2305054

2.2.1

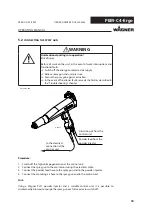

SAFE HANDLING OF WAGNER POWDER SPRAY UNITS

2.2.2

EARTH THE UNIT

2.2.3

MATERIAL HOSES

2.2

SAFETY INSTRUCTIONS FOR STAFF

➞

Only use original Wagner powder hose.

Always follow the information in these instructions, particularly the general safety

instructions and the warning instructions.

Always follow local regulations concerning occupational safety and accident

prevention.

Under no circumstances should persons with pacemakers be in the area where the

high voltage field between the spray gun and the workpiece to be coated builds up!

Never point the powder spray gun at people.

Before all work on the unit, in the event of work interruptions and functional faults:

– Switch off the energy/compressed air supply.

– Secure the powder spray gun against actuation.

– Relieve the pressure from the powder spray gun and unit.

– By functional faults: Identify and correct the problem, proceed as described in chap.

“Trouble shooting“.

The electrostatic charge may, in certain cases, give rise to electrostatic charges on the

device. These can involve with unloading transmitting or flame formation.

ª

Ensure that the device is grounded before each coating process.

ª

Earth the workpieces being painted.

ª

Ensure that all persons inside the working area are earthed, e.g. that they are wearing

antistatic shoes.

ª

Grounding cables must be checked regularly to ensure that they are serviceable

(see EN 60204).

2.2.4

CLEANING

De-energize the unit electrically.

Disconnect the pneumatic supply line.

Relieve the pressure from the unit.

Secure the control unit against being switched back on without authorisation.

Only mobile industrial vacuum cleaners of design 1 (see ZH 1/487 for C dusts) may be

used for getting rid of dust build-ups.