Extension cable PlastCoat 25

The cross section of the cable must be

min. 3 x 2.5 mm

2

. Unwind extension

cable completely. Make sure that the

couplings and plugs are in complete

working order.

Extension cable PlastCoat 35

The cross section of the cable must be

min. 5 x 2.5 mm

2

. Unwind extension

cable completely. Make sure that the

couplings and plugs are in complete

working order.

Arrange the mains cable so that there is

no danger of it being tripped over.

Protect against damage, e.g., caused by

it being run over.

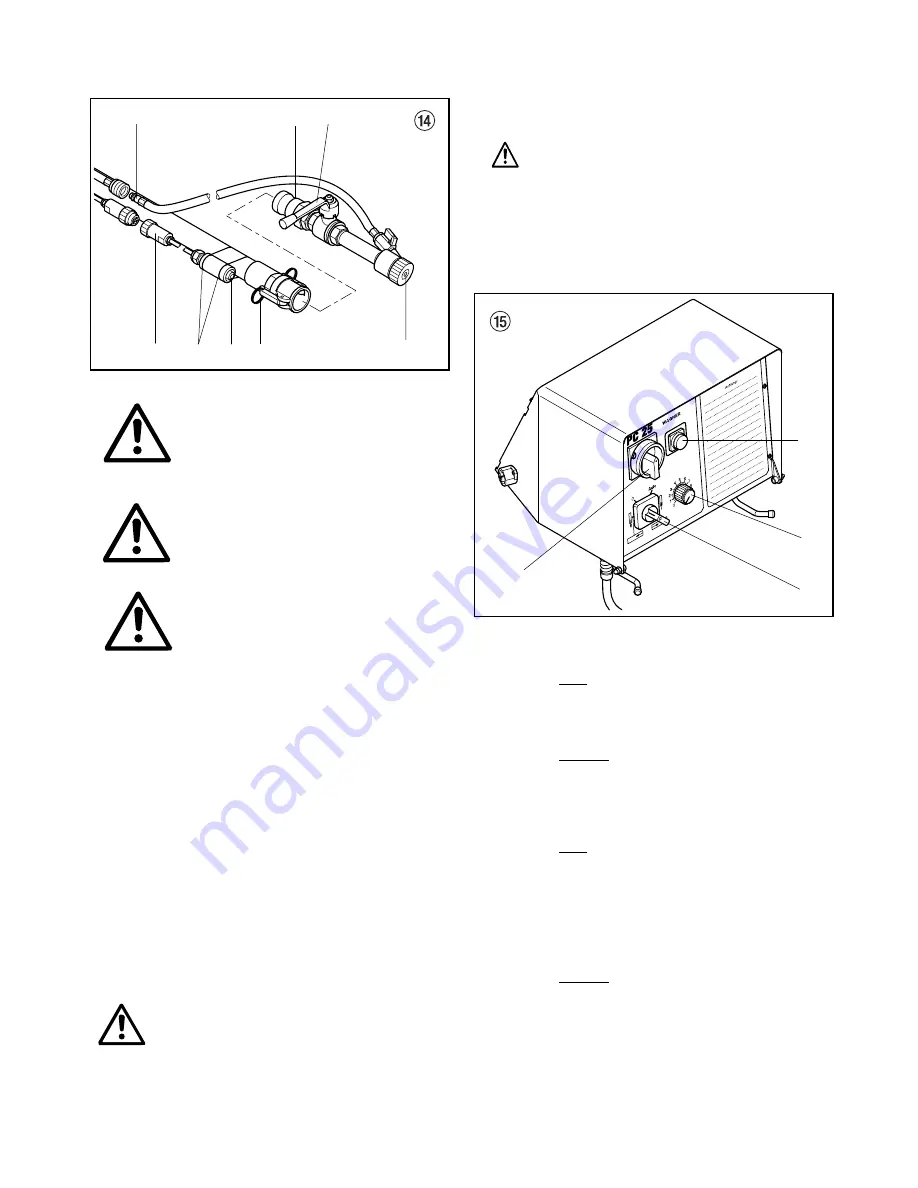

• Before connecting to the mains make sure that the

mains voltage is in accordance with the details on the

rating plate.

PlastCoat 25

• Only connect to the mains supply using a special

distributing point, e.g. using a site distribution system

with fault current protection with INF

≤

30 mA.

PlastCoat 35

• Only connect to the mains supply using a special

distributing point, e.g. using a site distribution system

with fault current protection.

• Connect mortar spraying machine to the mains supply.

Preparing the mortar spraying machine

Recommended lubricant for the mortar hose

Water is not a satisfactory lubricant.

Danger of blockages!

Synthetic resin products –> synthetic resin

dispersion

PCC systems

–> cellulose paste

• Fill 2–3 l synthetic resin dispersion or cellulose paste

into the receptacle.

•

Caution:

set changeover switch (4, fig. 15) to "0"

before turning on the master switch (1, fig. 15).

The pump is switched on, even if the feed

rate regulator is at position "0".

• Turn master switch (1, fig. 15) to "1", the indicator lamp

will show that the machine is ready for operation.

• Set feed rate regulator (3) to "5".

• Turn changeover switch (4) to "AUTO" (remote control

using spray lance).

• Hold spray lance over an empty bucket.

Spray lance with automatic control

• Open material tap (3, fig. 16) on the spray lance. The

mortar spraying machine will switch on.

Spray lance without automatic control

• Open material tap (3, fig. 17) on the spray lance. Press

remote control switch (1, fig. 17). The mortar spraying

machine will switch on.

Spray lance with automatic control

• When the synthetic resin dispersion or cellulose paste

has been pumped into the mortar hose – turn off

device, turn switching sleeve (1, fig. 16) by 90

°

in a

clockwise direction as far as it will go.

• Close material tap (3, fig. 16).

Spray lance without automatic control

• When the synthetic resin dispersion or cellulose paste

has been pumped into the mortar hose – turn off

device with remote control switch (1, fig. 17).

• Close material tap (3, fig. 17).

35

g

7

1

6

2

8

3

5

4

2

3

4

1

Summary of Contents for Plast Coat 25

Page 1: ...Ow n e r s Ma n u a l...

Page 10: ...Tabelle Teil 1 32 g...

Page 11: ...Tabelle Teil 2 33 g...