Fault

Pressure on the pres-

sure gauge increases

to over 40 bar.

Mortar spraying

machine does not

transport sufficient

coating material.

Mortar spraying

machine does not

start

Possible cause

Viscosity of the coating material too high.

Mortar hose diameter too narrow.

Mortar hose too long.

Flow speed selected too low.

Mortar hose diameter too narrow.

Pump jacket worn.

Viscosity of the coating material too high.

Texture nozzle too small.

The mortar spraying machine has been

overloaded.

41

Remedy

Dilute the coating material.

Use a mortar hose with a larger diameter.

Use shorter mortar hose.

Set feed rate to a higher setting.

Use a mortar hose with a larger diameter.

Install new pump jacket and, if necessary,

new pump screw.

Caution:

Spray with pump antiseize.

Dilute coating material.

Select a larger texture nozzle.

Set master switch and changeover switch to

"0".

Turn mortar spraying machine back on after

about 20 sec.

Caution

: set changeover switch to "0"

before turning on master switch.

If none of the above-mentioned possible causes was the reason for malfunction, there must be

a defect which will be repaired by the WAGNER after-sales service.

12 Servicing

•

Keep the threads for the star grips clean and oiled.

•

Spray pump screw and pump jacket with pump

antiseize.

•

Geared-motor is maintenance-free.

Electrical equipment

Check lines and plug connections. Rectify faults such as

loose connections, smoldered wires or dirty or damp

plug connections immediately.

Work and repairs on the electrical

equipment may be carried out only

by a qualified electrician even if the

product is accompanied with

operating instructions. We are unable

to assume liability for the con-

sequences of incorrect installation.

Long-term storage

If it is intended to store the machine for a long period, it

must be thoroughly cleaned and protected against

corrosion beforehand.

g

Summary of Contents for Plast Coat 25

Page 1: ...Ow n e r s Ma n u a l...

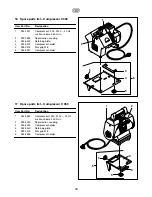

Page 10: ...Tabelle Teil 1 32 g...

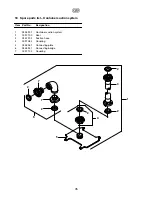

Page 11: ...Tabelle Teil 2 33 g...