42

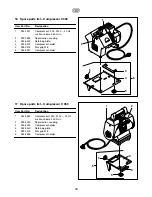

g

1

0348 363

0348 363

Motor cable

2

9982 820

9982 820

Cable screw connection

3

9982 823

9982 823

Adapter

4

0348 230

–––––––

Transmission motor 230 V

앑

, 50 Hz

–––––––

0348 231

Transmission motor 400 V, 50 Hz, V3

앑

5

9900 204

9900 204

Hexagon screw M 8 x 35 DIN 931 (2)

6

9920 102

9920 102

Washer A 8,4 DIN 125

7

9900 125

9900 125

Hexagon screw M 8 x 50 DIN 933

9

0348 334

0348 334

Supporting ring

10

9972 331

9972 331

Grooved ring 32 x 50 x 10

11

0348 400

0348 400

Intermediate flange

12

9971 171

9971 171

O-Ring 90 x 3,5

14

9930 913

9930 913

Straight pin 8 x 40

15

0348 324

0348 324

Screw

16

9921 518

9921 518

Lock washer B12 DIN 127

17

0348 313

0348 313

Carrier bush

18

9922 746

9922 746

Snap ring A 45

19

0348 314

0348 314

Feed screw

21

0348 329

0348 329

Grating

22

0348 307

0348 307

Receptacle

23

9900 109

9900 109

Hexagon screw M 8 x 25 DIN 933

24

0348 396

–––––––

Type plate PlastCoat 25

–––––––

0348 397

Type plate PlastCoat 35

25

9910 107

9910 107

Hexagon nut M8 DIN 934

26

0348 310

0348 310

Receptacle seal

27

0348 306

0348 306

Receptacle lower part

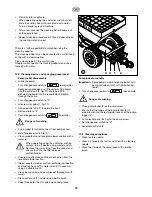

13 Spare parts list PlastCoat 25 and 35

(Spare parts illustration, see page 96)

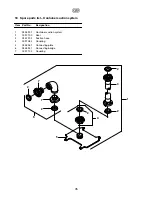

30

9910 208

9910 208

Hexagon nut M 8 DIN 985

31

9900 118

9900 118

Hexagon screw M 8 x 30 DIN 933

32

0348 316

0348 316

Pump screw yellow W 10/3 (standard)

33

0348 315

0348 315

Pump jacket yellow W 10/3 (standard)

34

9990 368

9990 368

Star grip M 16

35

0342 321

0342 321

Adapter fix-nipple V 35-M 27

36

0348 233

0348 233

Outlet unit

37

9990 618

9990 618

Coupling

38

9970 109

9970 109

Sealing ring

39

9991 946

9991 946

Pressure gauge

40

9991 947

9991 947

Protective cap

41

0348 349

0348 349

Wheel

42

9994 902

9994 902

Wheel cap

43

0348 419

0348 419

Trolley frame

44

9900 317

9900 317

Cheese head screw M 8 x 50 DIN 912

45

9990 863

9990 863

Pipe end cap

46

0348 318

0348 318

Drawbar tube right

47

9920 103

9920 103

Washer A 6,4 DIN 125

48

9910 204

9910 204

Hexagon nut M 6 DIN 985

49

0348 347

0348 347

Drawbar pipe left

50

0348 422

–––––––

Device mains connection H07 RN-F3G2,5 – 6 m

–––––––

0348 424

Device mains connection H07 RN-F5G1,5 – 6 m

51

9982 822

9982 822

Cable screw connection

52

9951 063

9951 063

Hexagon nut

53

9951 078

9951 078

Hexagon nut

Item

Part No.

Part No.

Designation

PlastCoat 25

PlastCoat 35

Item

Part No.

Part No.

Designation

PlastCoat 25

PlastCoat 35

Summary of Contents for Plast Coat 25

Page 1: ...Ow n e r s Ma n u a l...

Page 10: ...Tabelle Teil 1 32 g...

Page 11: ...Tabelle Teil 2 33 g...