g

46

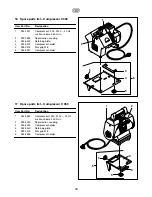

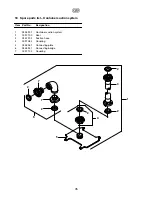

19 Accessories PlastCoat 25 and 35

(Accessories illustration, see page 98/99)

Item

Part No.

Designation

1

0268 779

Texture nozzle 4

0348 915

Texture nozzle 5

0268 780

Texture nozzle 6

0348 916

Texture nozzle 7

0268 781

Texture nozzle (standard)

0348 917

Texture nozzle 9

0268 782

Texture nozzle 10

0342 327

Texture nozzle 12

0268 905

Texture nozzle set 4, 6, 8, 10

2

0342 916

Cleaning needle

3

0342 330

Cleaning ball for DN 19 mm

0342 331

Cleaning ball for DN 27 mm

0342 332

Cleaning ball for DN 35 mm

4

0342 329

Bottle brush for cleaning the inside

of the outlet unit and spray lance

5

9992 824

Pump antiseize 500 ml

6

0342 215

Hose holder

7

0342 241

Cleaning adapter M 27 – GK

0348 948

Cleaning adapter M 35 – GK

8

0342 321

Adapter fix-nipple V 35 – M 27

9

0348 946

Mortar hose DN 35 – 13.3 m,

connection V 35 – M 35

0348 912

Mortar hose DN 27 – 10 m,

connection V 27 – M 27

0348 930

Mortar hose DN 19 – 20 m,

connection V 27 – round thread

32 x 1/8 in

0348 909

Mortar hose DN 19 – 10 m,

connection V 27 – round thread

32 x 1/8 in

0342 255

Mortar hose DN 19 – 2 m,

connection V 27 – round thread

32 x 1/8 in

10

9952 672

Plug

11

0342 314

Seal fix-coupling M 27

9971 531

Seal fix-coupling M 35

12

9952 673

Coupling plug

13

0268 216

Pressure switch for remote control of

spray lance without automatic control

14

9983 238

Double nipple 3/4 in – round thread

32 x 1/8 in

15

0342 200

Spray lance 100 mm long

without automatic control

Item

Part No.

Designation

16

0348 224

Spray lance 100 mm long

with automatic control

17

0348 931

Angled spraying head 70

°

for spray lance with automatic control

18

0348 904

Extension kit 500 mm long

material pipe and air pipe) for spray lance

with automatic control

0348 923

Extension kit 800 mm

(material pipe and air pipe)

for spray lance with automatic control

19

0348 919

Spray lance (ceiling spray lance)

800 mm long with automatic control

20

0342 912

Rendering lance 200 U

21

0268 726

Rendering nozzle set 14, 16, 18

22

0342 240

Texture spraying head for application gun

23

0342 246

Application gun, connection V 27

for the application of heat insulation

composite system adhesive

24

0342 231

Compressor V 400, 230 V AC,

50Hz,suction volume 360 l/min

without automatic switch-off

0342 906

Compressor V 400, 230 V~, 50 Hz,

suction volume 360 l/min

with automatic switch-off

25

0348 957

Compressor holder V 400

26

0348 955

Compressor C 350, 230 V~, 50 Hz,

suction volume 350 l/min,

without automatic switch-off

27

0348 956

Compressor holder C 350

28

0348 316

Pump screw yellow (standard)

0348 926

Pump screw brown

0348 928

Pump screw green

29

0348 315

Pump jacket yellow (standard)

0348 925

Pump jacket brown

30

0348 927

Pump jacket green, re-tightenable

31

0348 907

Container suction system

32

0348 908

Sliding cover for receptacle

33

0268 728

Sack mangle

34

0348 958

Accessory box with various accessories

Summary of Contents for Plast Coat 25

Page 1: ...Ow n e r s Ma n u a l...

Page 10: ...Tabelle Teil 1 32 g...

Page 11: ...Tabelle Teil 2 33 g...