8.

Prevent the socket for the remote control on the

control unit from getting dirty.

Always leave the coupler plug of the remote control

line on the mortar hose screwed complete into the

control unit.

9.

Danger of injury from the screw

conveyor.

Never put your hands into the

receptacle when the mortar

spraying machine is running.

Never turn on the mortar spraying machine when

the grating has been removed from the

receptacle, when the receptacle has been

removed or if there is no container connection

plate.

10. Cleaning and servicing

Never uncouple mortar hoses under pressure.

Before uncoupling, check pressure on the pressure

gauge.

Turn off the mortar spraying machine for cleaning

and maintenance work. Pull out mains plug and

ensure that it cannot be plugged back in

unintentionally.

Do not spray the motor or control unit of the mortar

spraying machine with water jet, high-pressure or

steam cleaning equipment. Water could penetrate

the machine and cause a short-circuit.

11. Electrical equipment

Work on the machine’s electrical equipment may be

carried out only by a qualified electrician.

The electrical equipment must be inspected regu-

larly. Defects such as loose connections or

scorched cables must be remedied immediately.

12. Keep the labels on the mortar spraying machine

clean and legible.

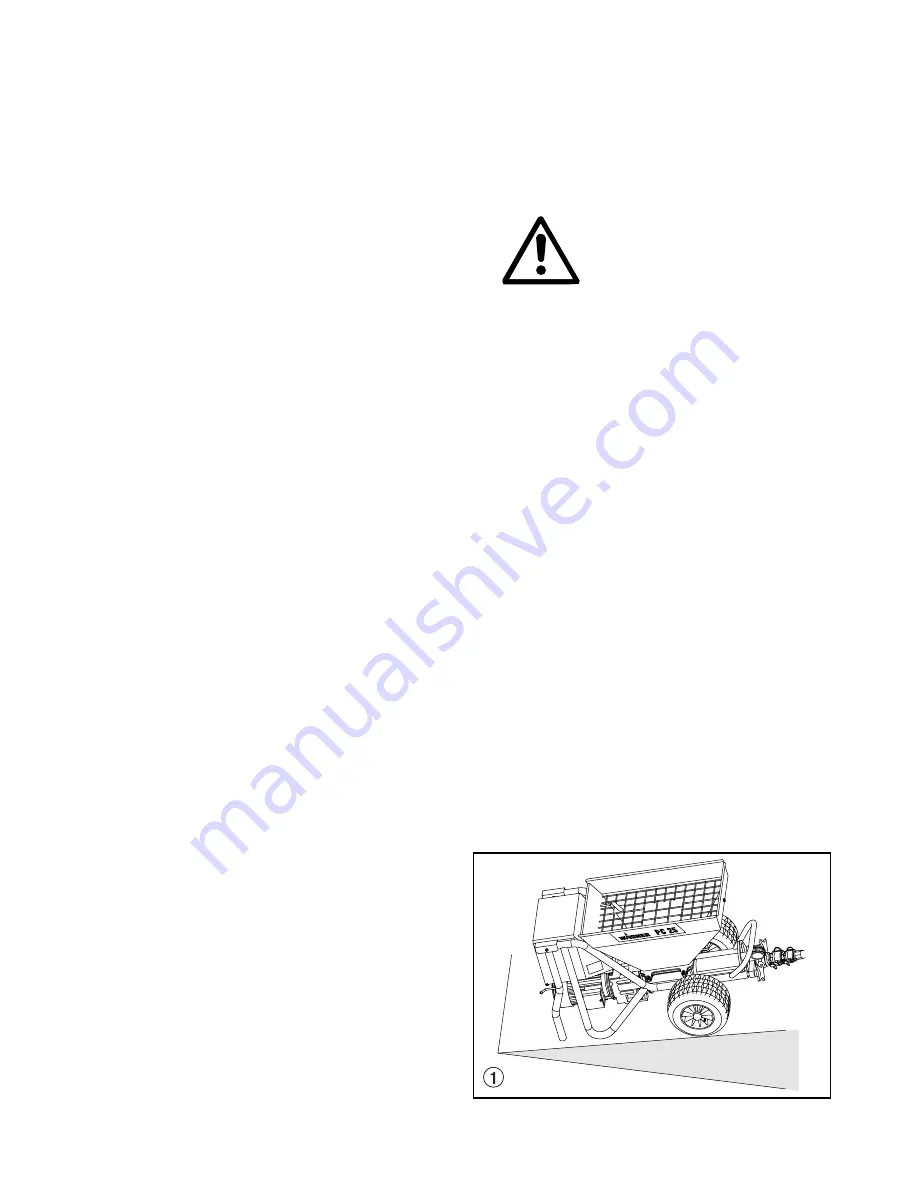

13. Positioning on uneven ground

The front of the mortar spraying machine must point

upwards to avoid that the machine slips away.

1

Safety requirements

All local safety regulations in force must be

observed.

For safe operation of the mortar spraying machines,

always comply with the following specific instructions:

1. Use of the mortar spraying machines

The mortar spraying machines PlastCoat 25 and

35 are designed only for the spraying of the

materials described on page 27.

Any other use is not permitted. The manufacturer

cannot be held liable for any damage resulting

from this. In such cases, the risk will be borne

solely by the user.

Intended use also includes compliance with the

Operating manual and compliance with the

inspection and servicing conditions.

Always keep the Operating manual ready at hand

at the machine location.

2. The mortar spraying machines PlastCoat 25 and

35 may only be operated with a pressure gauge.

Only the mortar hose prescribed by the

manufacturer may be used.

3. Only use identified mortar hoses with an

operating pressure of at least 40 bar.

4. Personnel safety

Always wear protective goggles, protective clothing

and gloves and, if necessary, skin barrier cream and

breathing equipment, to protect your eyes, skin and

respiratory system.

Never uncouple mortar hose while it is still under

pressure.

Note pressure gauge!

Wear protective goggles!

Never aim spray lance at any person!

5. Breathing masks

Breathing masks must be provided for the operator

to protect against mineral dust.

6. PlastCoat 25

Only connect to the mains supply using a special

distributing point, e.g. using site distribution

system with fault current protection with

INF

≤

30 mA.

PlastCoat 35

Only connect to the mains supply using a special

distributing point, e.g. using a site distribution

system with fault current protection.

7. The master switch has an EMERGENCY OFF

function.

26

DANGER

g

Summary of Contents for Plast Coat 25

Page 1: ...Ow n e r s Ma n u a l...

Page 10: ...Tabelle Teil 1 32 g...

Page 11: ...Tabelle Teil 2 33 g...