39

Plast Coat 25 · 35

GB

9

FIttING ACCeSSORIeS

9.1

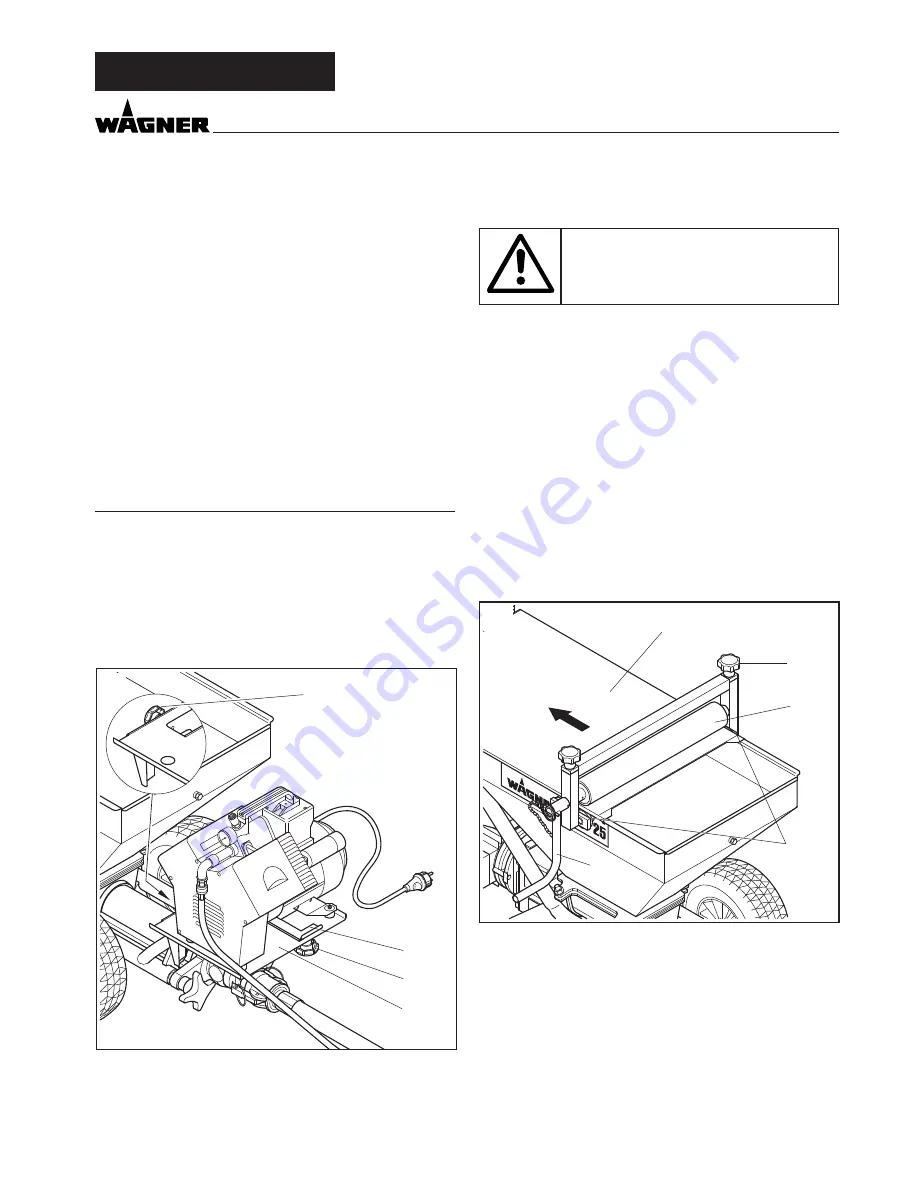

COMPReSSOR

V 400 suction volume 360 l/min

• Attach compressor holder (item 1, fig. 17) and secure with

star grip (2).

• Place compressor onto holder. Slide retaining plate (3) over

the compressor base.

• Secure the compressor with star grips (4).

technical data

Roller length: 465 mm

Roller diameter: 66 mm

Weight: 6.7 kg

Putting sack mangle into operation

• Connect crank handle (1, fig. 18) and secure with linch pin.

• Insert sack mangle and sliding cover (2, accessory).

• Screw out star grips (3) about 2 cm.

• Place sack mangle and crank handle (1) on the sliding cover

to the right from the front. Move guide rollers (4) over stop

pins on the underside of the sliding cover.

• Adjust pressure force of the roller (5). Turn the star grips (3)

to the right until they will go no further.

• Turn crank and move sack mangle to the rear as far as it will

go.

material delivery rate and air delivery rate.

fine texture

––> larger air delivery rate

coarse texture

––> low air delivery rate

Higher material

delivery rate

––> higher air delivery rate

We recommend that you test the required texture on a sample

surface.

To improve the „feathering effect“ in order to allow easier over-

lap, choose an appropriate distance between the spray lance

and the object surface.

The spray margin should „feather out“ to allow easier overlap-

ping.

Considerably less spray mist is produced if the spray lance is

always guided at 90° parallel to the spray surface.

Note:

Sharp-edged grains and pigments will increase wear on the

pump, hose, material ball valve and tip.

danger of crushing.

do not pace hands under the roller.

9.2

SACk MANGle

Safety note

fIttIng accessorIes

3

2

1

4

4

1

5

2

3

Summary of Contents for Plast Coat 25

Page 25: ...49 Plast Coat 25 35 GB...

Page 32: ...109 Plast Coat 25 35...