41

Plast Coat 25 · 35

GB

10.2

CleANING deVICe ANd CHANGING PuMP

jACket

Never remove the safety grill for any clea-

ning work!

disassembly

• Lubricate pump.

Turn changeover switch to

(backwards).

Spray pump antiseize or a little dishwashing liquid into the

outlet unit (2, fig. 22) or place a little dishwashing liquid into

the receptacle and pump through the pump.

• Turn changeover switch to „0“.

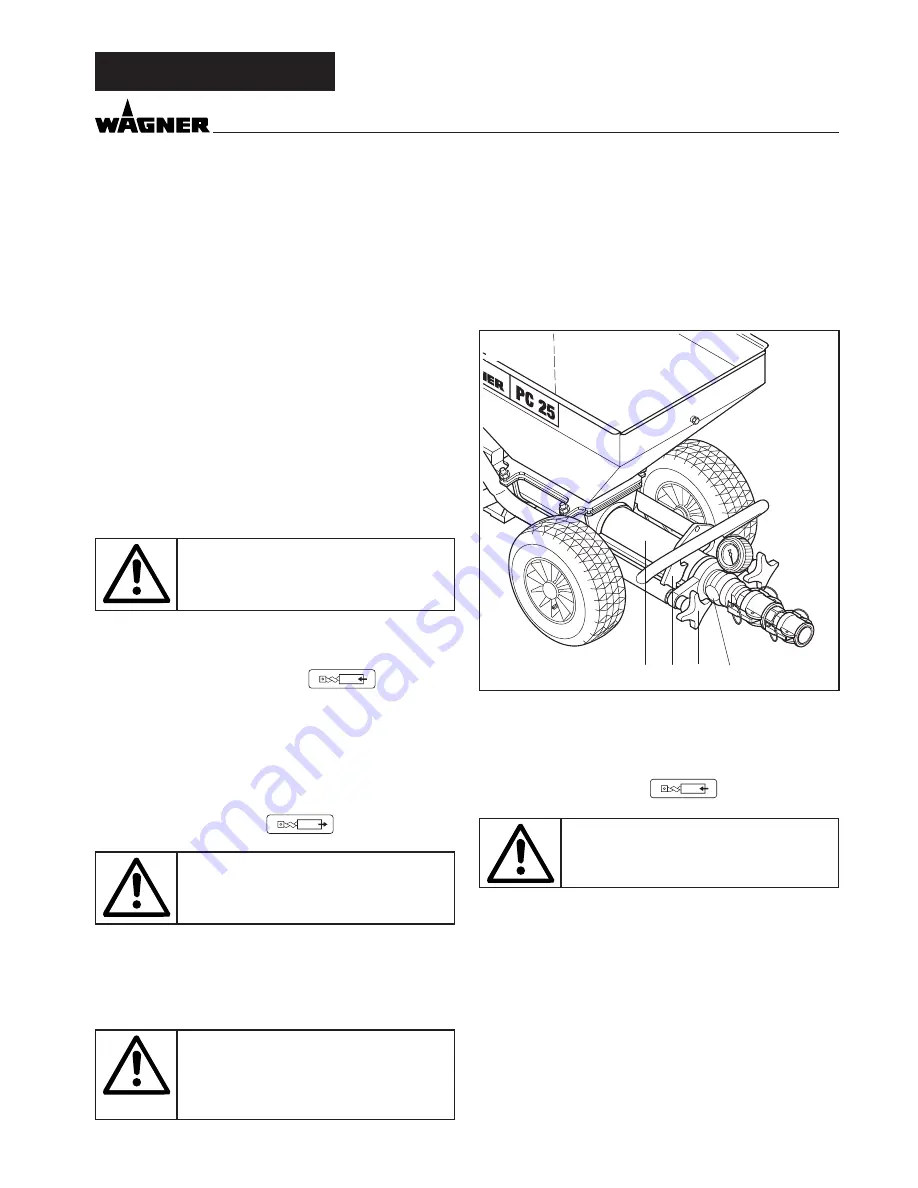

• Unscrew star grips (1, fig. 20).

• Remove outlet unit (2) towards the front.

• Set feed rate to „3“.

• Turn changeover switch to

(forwards).

danger of crushing!

• Pump jacket (3) will disconnect from pump screw.

• Set changeover switch to „0“.

• Clean receptacle and receptacle lower section with a water

jet.

When operating using the container suc-

tion system, turn off device using master

switch. Remove the mains plug from the

socket and ensure that it cannot be re-

placed unintentionally.

• Unscrew and remove container connection from the recep

-

tacle lower section.

• Clean receptacle lower section, container connection and

suction hose with a water jet and, if necessary, using a suit-

able brush.

• Clean pump screw and pump jacket thoroughly with water.

• Clean outlet unit (2) inside using a bottle brush.

• Keep threads for the star grips clean and grease.

Pump jacket assembly

Important:

Spray pump screw and pump jacket with pump antiseize or

wet with dishwashing liquid.

• Turn changeover switch to

(backwards).

danger of crushing!

• Place pump jacket (3, fig. 20) onto pump screw. Ensure that

the ledge of the pump jacket (3) is properly slid into the rec-

tangular recess of the pump trigger (4).

• Pump jacket pulls itself onto the pump screw.

• Set changeover switch to “0”.

• Assemble outlet unit.

10.3

CleANING SPRAy lANCe

• Clean texture nozzle.

• Clean air holes in the texture nozzle with a cleaning needle.

• Clean the inside of the spray lance with a bottle brush.

• Disconnect the mortar hose from the outlet section.

• Insert cleaning ball in the mortar hose.

Re-connect the mortar hose.

• Fill water into receptacle.

When operating using the container suction system, im-

merse suction hose into receptacle with water.

Turn on mortar spraying machine.

• After a few seconds the cleaning ball will come out of the

spray lance.

• Repeat cleaning procedure 3–4 times, depending on the

coating material used.

There is a further possibility for cleaning using the cleaning

adapter.

This cleaning adapter can be connected to a water hose or

tap with a claw coupling.

Place cleaning ball in the mortar hose. Couple mortar hose to

the cleaning adapter and rinse through with water.

placIng out of operatIon and cleanIng

3

2

1

4

Summary of Contents for Plast Coat 25

Page 25: ...49 Plast Coat 25 35 GB...

Page 32: ...109 Plast Coat 25 35...