32

Plast Coat HP 30

EN

TRANSPORTATION / COMMISSIONING

5

TRANSPORTATION

5.1

MOVING

Wind power cable around handle and remove the hose.

Put away the nozzles and other small objects in the storage

compartment.

Push or pull the PC HP 30 by the handle.

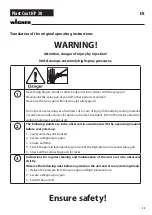

Appliance weighs over 70 kg. Only lift or

carry the appliance with at least 3 people.

5.2

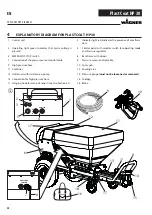

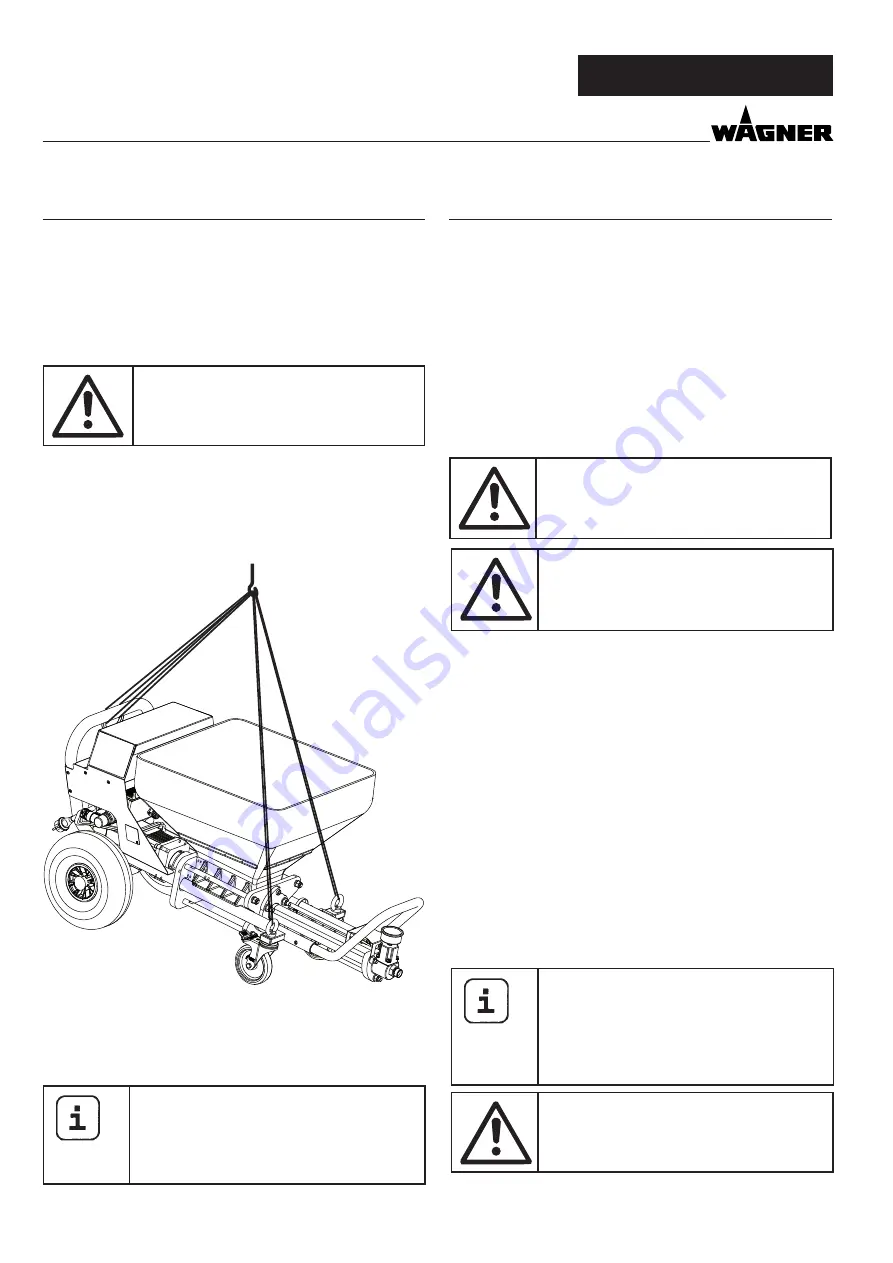

TRANSPORT USING A CRANE (FIG. 4)

For attaching points for the straps or rope (not wire cable) see

figure.

5.3

TRANSPORTATION IN VEHICLE

Secure the unit in the vehicle by means of suitable fasteners.

To avoid material residues leaking from the

machine, clean the device in advance or lock

the mortar connection. Do not fill the contain-

er completely full in order to prevent material

from splashing out of it.

6

COMMISSIONING

6.1

INSTALLATION LOCATION

Ideally only place the machine on flat surfaces in order to stop

it from sliding away.

• Before connecting the unit to the mains supply, ensure that

the line voltage matches that specified on the rating plate.

Min. wire cross-section 3 x 2.5 mm

2

. Unroll the

extension cable completely. Ensure that the

coupling pieces and plugs are free of damage.

Lay the device supply cable so that there is no

danger of stumbling.

Protect against damage, for example against

being driven over.

6.1.1

CONNECTION TO MAINS POWER SUPPLY/

EXTENSION CABLE

Connection to the mains network only via a special feed-

ing point, for example via a distribution board for con-

struction sites, with residual current protective device

with INF

≤

30 mA.

6.2

INITIAL STARTING-UP

6.2.1

SCOPE OF SUPPLY

The machine is supplied by the manufacturer in the following

individual components:

• Complete basic machine comprising drive unit, control unit,

receptacle and transport frame with wheels

• Hose package (incl. hose whip)

• Spray gun

• Pump sliding means

• Toolbag with nozzles, cleaning accessories, double open

ended spanner,...

6.3

PREPARING THE MACHINE

At delivery, the pump unit is filled with con-

servation agent (PlastGuard longlasting, Art.

No. 2399 960). At initial commissioning and

with each subsequent use of this conservati-

on agent, it should first be pumped fully out

before work commences.

Do not use any water during commission-

ing to flush the conservation agent out.

Doing so could cause the rotor and stator

to seize, requiring them to be replaced.

• Place a flat trough under the hose connection.

• Check that the pump unit is seated firmly.

Summary of Contents for PLAST COAT HP 30

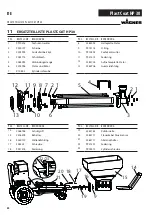

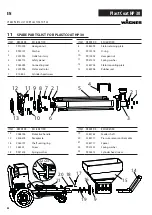

Page 45: ...45 Plast Coat HP 30 EN PlastCoat HP 30 Accessories illustration 1 9 11 10 5 6 8 2 3 4 7 8 13...

Page 67: ...67 Plast Coat HP 30 DA PlastCoat HP 30 Tilbeh rsbillede 1 9 11 10 5 6 8 2 3 4 7 8 13...

Page 89: ...89 Plast Coat HP 30 SV 1 9 11 10 5 6 8 2 3 4 7 8 13 PlastCoat HP 30 Tillbeh rsbild...