39

Plast Coat 1030

GB

6.4

COMPRESSOR (ACCESSORY)

Place the compressor at a secure location next to the mortar

spraying machine and connect it to the mains network.

Note:

Only operate the compressor in accordance with the enclosed

operating manual.

6.5

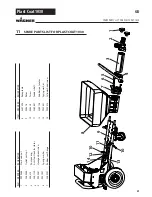

SPRAY ATTACHMENT ASSEMBLY (ACCESSORIES)

Different accessories can be mounted to the

spray lance, depending on the application,

e.g. an extension can be attached. A precise

overview can be found in the “Accessories”

chapter.

• Disengage the quick connector and pull the air hose (fig. 8,

1) out of the lance.

• Loosen the locknut (2) and remove the material hose (3).

• Insert the material hose and air hose (if available), which

are part of the accessory, into the spray lance and secure

by tightening the locknut. (Fig. 9)

Attention: Make sure the O-ring (fig. 9, 4) is not dam-

aged.

6.6

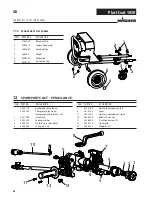

CONNECTING THE SPRAY LANCE (FIG. 10)

• Select a spray tip suitable for the material:

The tip size should amount to at least three times the

granular size, e.g.

granular size artificial resin plasters –> 3 mm

Tip size –> 10 mm

• Mount the texture tip (1) in the spray lance with the cone

pointing towards the spray head.

• Connect the spray lance (2) to the material hose and secure

by applying the levers (3).

• Close the material tap (4) (material tap points forwards).

• Connect atomization air connection (5) to the air hose of the

mortar hose.

• Screw coupling plug (6) for remote control to the control ca-

ble of the mortar hose.

• Connect mortar hose‘s control cable to pump connection.

(Fig. 11)

• Set selector switch to “A”.

COMMISSIONING

햹

3

1

2

햺

4

REMOTE

Control

ELEC

PNEUM

Controler

햽

햻

2

4

1

3

6

5

Summary of Contents for PLASTCOAT 1030

Page 51: ...51 Plast Coat 1030 GB...

Page 79: ...79 Plast Coat 1030 F...

Page 110: ...110 Plast Coat 1030 NL...

Page 111: ...111 Plast Coat 1030 NL...