30

Prima Sprint

.

OPERATING MANUAL

VERSION 07/2009

ORDER NUMBER DOC 2305835

5.8

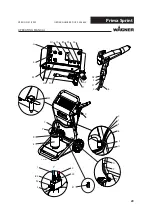

GROUNDING

For security reasons the manual system must be correctly grounded. Normally this is done

via the mains cable.

Good grounding of the workpiece is also necessary for optimum powder coating.

It is important to keep the earth cables as short as possible. Earth cables of an excessive

length must be shortened. Earth cables of an excessive length must never be wound up

on a roller.

A poorly grounded workpiece causes:

●

Dangerous electric charging of the workpiece.

●

Very bad wrap around.

●

Uneven coating.

●

Backspraying to the spray gun, i.e. contamination.

Prerequisites for perfect grounding and coating are:

●

Conducting suspension for the workpiece that is to be coated.

●

Grounding of the powder coating booth, transport and suspension equipment to

be provided on site, in accordance with the corresponding Operating manuals or the

defi nitions laid down by the manufacturer.

●

Regular cleaning of hangers from powder residues.

●

Grounding resistance for the workpiece of a maximum of 1 M

Ω

(mega ohm).

●

Grounding cable connected to the controller module or control cabinet.

Sparks between workpiece and conveyor hooks (hangers) can occur if hooks or

other hanger parts are not completely cleaned! These sparks can cause heavy radio

frequency interference (electro-magnetic compatibility = EMC).

Summary of Contents for Prima Sprint Airfluid

Page 2: ......

Page 96: ...96 Prima Sprint OPERATING MANUAL VERSION 07 2009 ORDER NUMBER DOC 2305835...

Page 124: ...124 Prima Sprint OPERATING MANUAL VERSION 07 2009 ORDER NUMBER DOC 2305835...

Page 125: ...125 Prima Sprint OPERATING MANUAL VERSION 07 2009 ORDER NUMBER DOC 2305835...

Page 127: ......