20

OPERATING MANUAL

VERSION 07/2017

ORDER NUMBER DOC 2349369

7.2.4 CLEANING THE AIRLESS NOZZLE

For disassembly and assembly of Airless nozzles, see Chapter

.

The Airless nozzle can be placed into a cleaning solution recommended by the paint manufacturer.

7.2.5 CELIMINATE NOZZLE CLOGGING

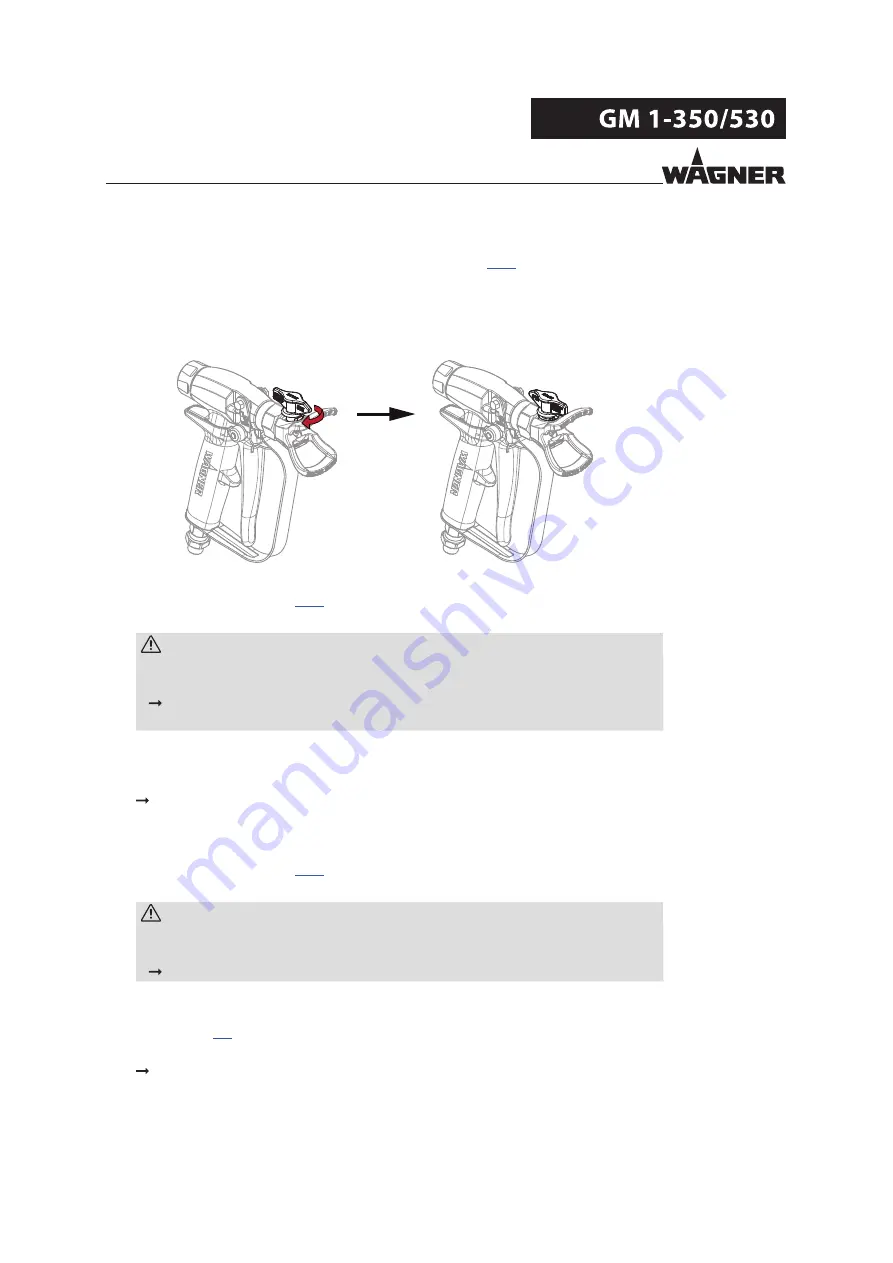

Nozzle holder PT-HD GM1

B_5054

1. Relieve the pressure on the spray gun and product pressure generator in

accordance with Chapter

.

2. Secure the spray gun with the locking device.

3.

CAUTION

Product emission from product inclusions between nozzle and valve seat!

Injury due to contact with dangerous liquids.

When turning or removing the reversing nozzle, always keep the spray gun

pointed at the ground.

Rotate the reversing nozzle 180° so that its tip is pointing opposite the direction of

spray.

4. Briefly trigger the spray gun so that the pressure eliminates the clog.

Only activate the trigger briefly if the nozzle is installed in the reversed direction.

Nozzle holder WAGNER Tip 7/8 UNF

1. Relieve the pressure on the spray gun and product pressure generator in

accordance with Chapter

.

2. Secure the spray gun with the locking device.

3.

CAUTION

Product emission from product inclusions between nozzle and valve seat!

Injury due to contact with dangerous liquids.

When loosening the nozzle, always keep the spray gun pointed at the ground.

Loosen nozzle by ¾ rotation.

4. Turn the nozzle 180° in accordance with supplement WAGNER Tip (For Order No.,

see Chapter

).

5. Briefly trigger the spray gun so that the pressure eliminates the clog.

Only activate the trigger briefly if the nozzle is installed in the reversed direction.