24

OPERATING MANUAL

VERSION 07/2017

ORDER NUMBER DOC 2349369

8.2.3 SAFETY CHECKS AND MAINTENANCE INTERVALS

Every day

Check grounding: see Chapter

Check hoses, tubes and couplings: see Chapter

Flush and clean the spray gun as described in Chapter

Weekly

Check spray guns for damage.

Check the function of the safety fixtures (see Chapter

):

– Anti-contact guard on nozzle holder.

– Guard bracket

– Trigger locking device must engage and block the trigger.

Yearly or as required

In accordance with DGUV regulation 100-500 Chapter 2.29 and 2.36:

– The liquid ejection devices should be checked by an expert (e.g., WAGNER

service technician) for their safe working conditions as required and at least

every 12 months.

– For shut down devices, the examination can be suspended until the next start-

up.

8.2.4 PRODUCT HOSES, TUBES AND COUPLINGS

The service life of the complete hoses between product pressure generator and application

device is reduced due to environmental influences even when handled correctly.

Check hoses, pipes, and couplings every day and replace if necessary.

Additionally, the operator must regularly check the complete hoses for wear and

tear as well as for damage at intervals that he/she has set. Records of these checks

must be kept.

The complete hose is to be replaced as soon as one of the two following intervals

has been exceeded:

- 6 years from the date of the hose crimping (see fitting embossing).

- 10 years from the date of the hose imprinting.

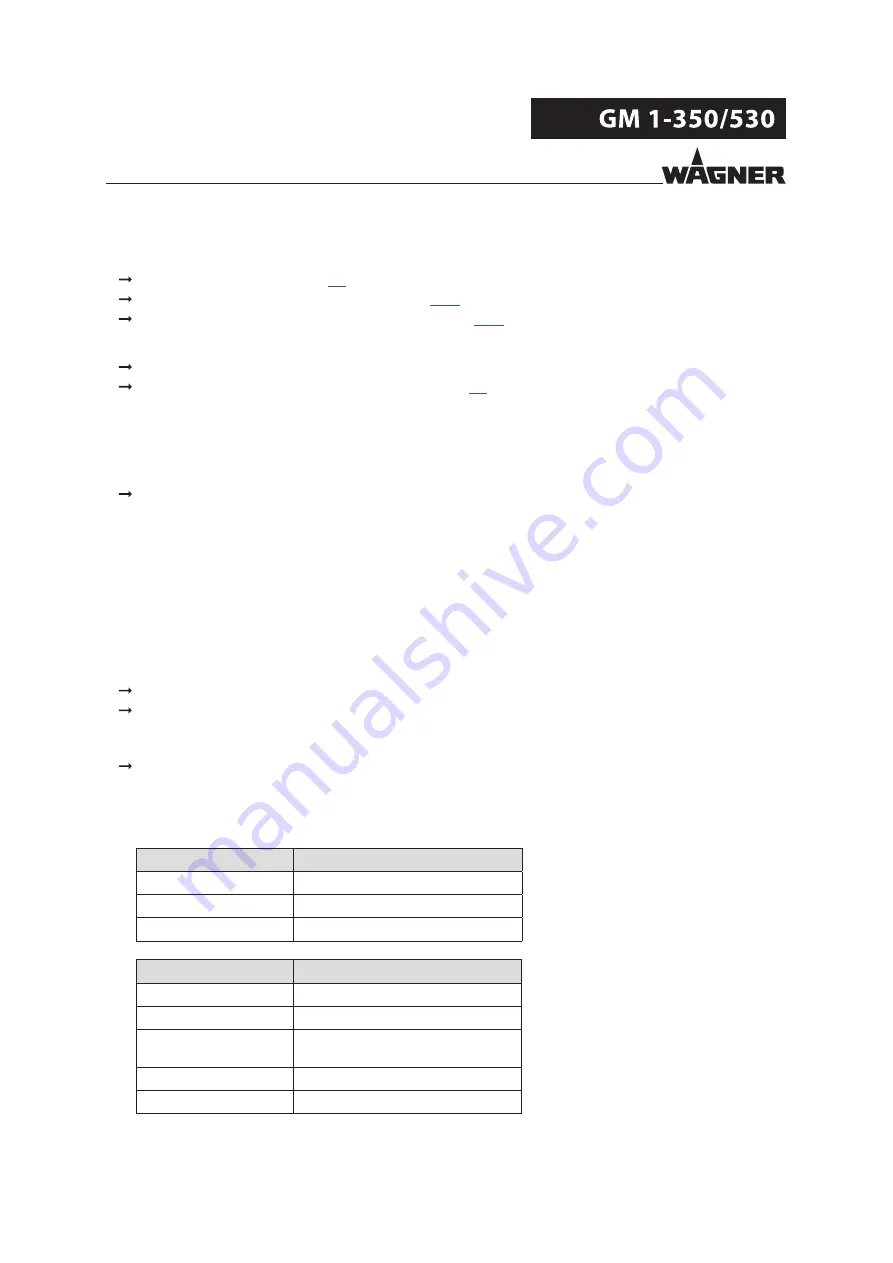

Fitting embossing

Meaning

xxx bar

Pressure

yymm

Crimping date (year/month)

XX

Internal code

Hose imprinting

Meaning

WAGNER

Name / Manufacturer

yymm

Date of manufacture (year/month)

xxx bar (xx MPa)

e.g., 270 bar (27 MPa)

Pressure

XX

Internal code

DNxx (e.g., DN10)

Nominal diameter