28

VERSION 06/2018

ORDER NUMBER DOC 2343275

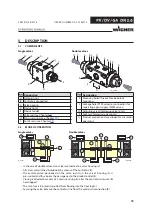

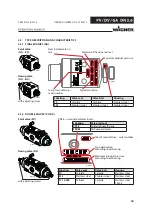

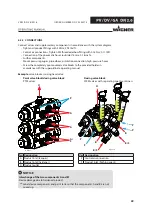

8.2.3 SAFETY CHECKS AND MAINTENANCE INTERVALS

WARNING

Heavy paint mist in the case of leaking!

Danger of poisoning.

Comply with maintenance intervals (tightness check).

Examine the compatibility of the cleaning agents and working media on the basis

of the safety data sheets.

Every day

PTFE valves: check leakage holes (L).

In case air or paint is emitted at the leakage holes:

B_03651

L

– Seals defective, replace (see Chapter

).

FFKM valves: Check separating agent (see Chapter

).

– In the case of soiled separating agent or foam formation/air bubbles:

– Replace separating agent and replace valve rod seals.

– Top up separating agent as necessary.

Check hoses, tubes and couplings: see Chapter

Yearly or as required

In accordance with DGUV regulation 100-500 Chapter 2.29 and Chapter 2.36:

− The liquid ejection devices should be checked by an expert (e.g., WAGNER

service technician) for their safe working conditions as required and at least

every 12 months.

− For shut down devices, the examination can be suspended until the next start-

up.