45

OPERATING MANUAL

VERSION 05/2017

ORDER NUMBER DOC 2354920

SPRINT XE

7.5

PERFORMING A PAINT CHANGE

7.5.1 AIRFLUID VERSION

Note:

For a paint change, all components of the powder feed system must be thoroughly cleaned.

P_01785

EPG

SPRINT X

0

%

10

20

30

40

50

Ø

12

10

11

9

8

m /h

2.0

3.0

0.5

0.3

0.1

1.5

3

5.5

4.5

3.5

2.5

80

100

%

Tri

90

60

70

P_1789

H

17

Procedure:

1.

Release the trigger on the spray gun.

The high voltage and the powder feed are

deactivated.

2.

Lift the feed unit up, underneath the injector,

and lift it out of the tank until retaining clamp

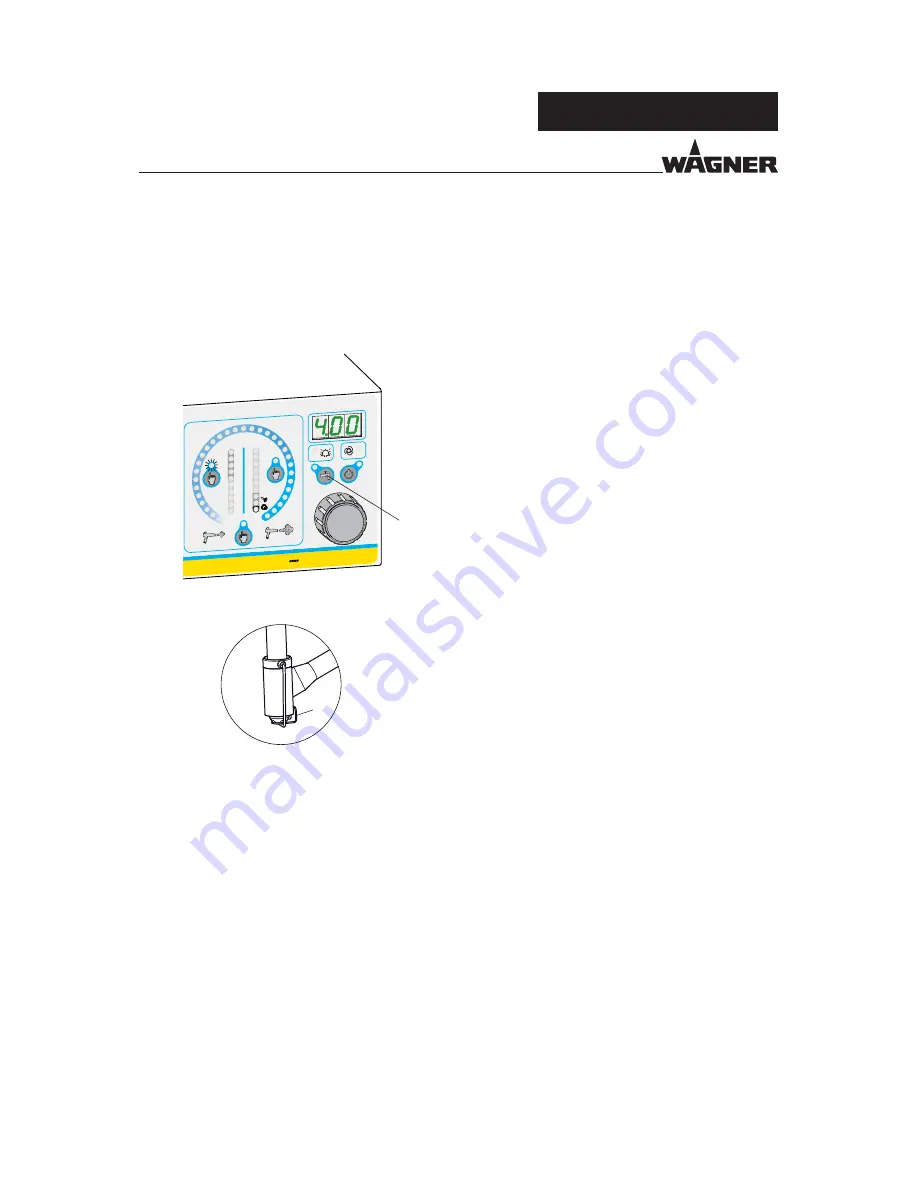

(H) swivels downwards.

3.

Lower the feed system into the parking position

and swivel it to the right side so that no more

powder is forwarded.

4.

Hold the gun in the spray booth and start the

fl ush function by pressing the "Flush" button (17).

The injector and hoses are fl ushed.

5.

Switch off control unit.

6.

Clean all powder feeding parts of the unit, such

as the spray gun, the injector and the powder

feed hose.

7.

Place an opened powder tank (25–30 kg; 55.11–

66.14 lbs) with the new powder on the vibrator

table.

8.

Swivel retaining clamp (H) away, lower the feed

unit to the powder surface, actuate the trigger

of the spray gun for a short time and then

release it.

9.

Adjust the fl uid air at the throttle to the point

that the feed unit sinks into the powder due to

its own weight.

To adapt the programs to the new applications proceed as described in the EPG-Sprint XE

control unit's operating manual.

Summary of Contents for Sprint 60 L XE

Page 2: ......

Page 85: ...85 OPERATING MANUAL VERSION 05 2017 ORDER NUMBER DOC 2354920 SPRINT XE ...

Page 87: ......