78

OPERATING MANUAL

VERSION 05/2017

ORDER NUMBER DOC 2354920

SPRINT XE

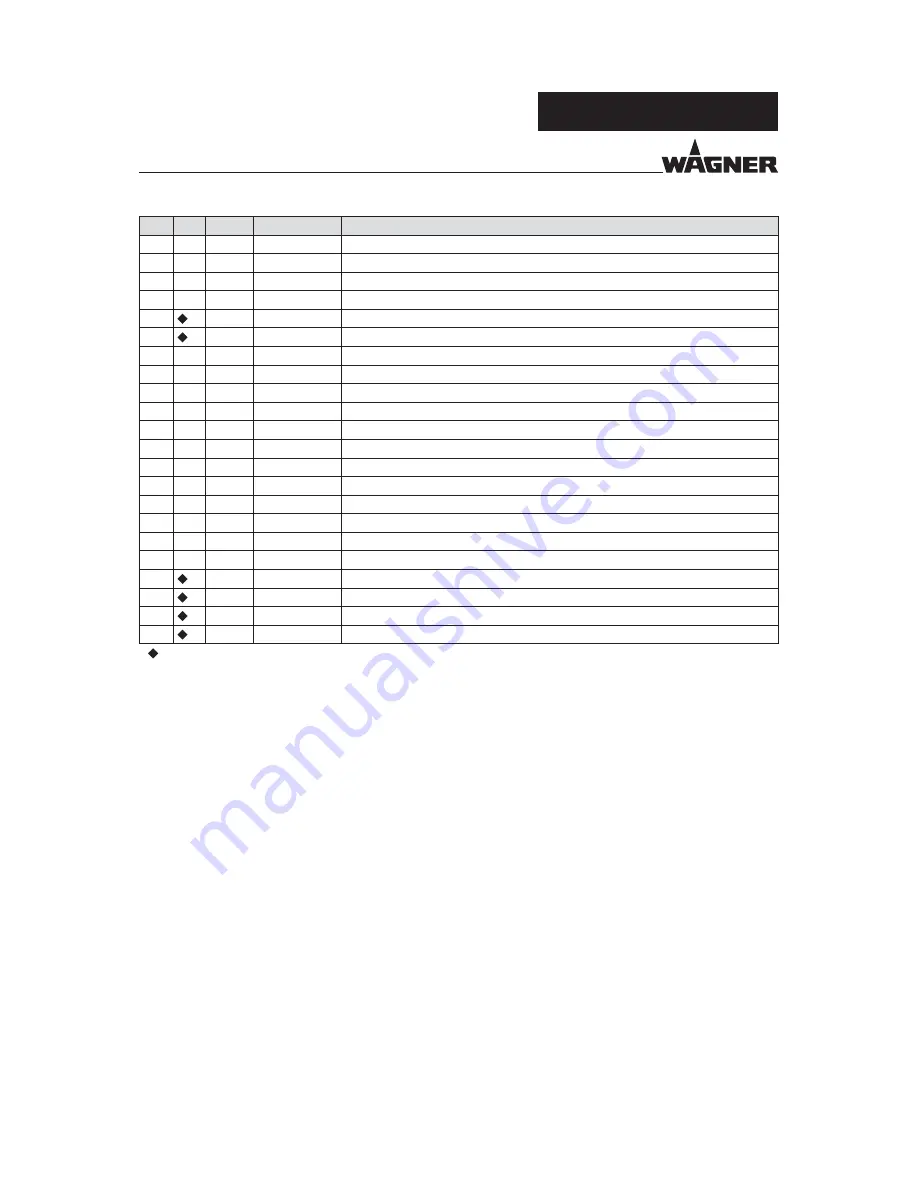

Pos K

Stk

Order No.

Designation

1

1

264268

Powder tank, 60 L

1

1

264224

Powder tank, 25 L

2

1

264215

Base housing

3

1

264381

Lid

4

1

264382

Fluidized bed

5

1.10 m

9971527

Foam rubber seal

6

6

9994703

Spring clip

7

12

9900717

Socket cap screw

8

1

9992270

Quick coupling for screw-on connector

9

1

184336

Hose fi tting

10

1

9910109

Hexagon nut

11

9982058

Exhaust hose, 17x3 mm

13

1

241372

Injector connection, complete

14

1

170533

Knurled nut

15

2

9920118

Washer

16

1

241276

Grounding cable, complete

17

12

9922102

Star washer

19

1

241376

Cable connection

20

1

263357

Intake tube, 60 L

20

1

264420

Intake tube, 25 L

21

1.10 m

8324008

Base seal

24

2

9971178

O-ring

= Wearing parts

Summary of Contents for Sprint 60 L XE

Page 2: ......

Page 85: ...85 OPERATING MANUAL VERSION 05 2017 ORDER NUMBER DOC 2354920 SPRINT XE ...

Page 87: ......