Operating manual Manual Powder System SPRINT XE

7 Operation

42

Order number 2354920 | Edition 01/2023

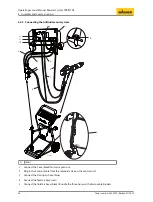

7.5.2.3 Restarting the manual system

1. Check if the control unit is switched off.

2. Open the powder tank.

WARNING

Dust formation!

Risk of poisoning if inhaled.

Danger due to escaping dust, contamination of the device and device components.

4

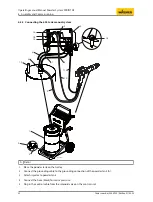

The powder tank may only be filled to the halfway mark, because fluidizing increases

the volume of powder.

3. Switch on the control unit and activate the [Powder Feed Quantity] function by

pressing the [Powder Quantity] button (36).

4. Adjust the powder quantity to 0% with the universal control dial (24).

5. Actuate the trigger lever and keep it actuated.

6. Adjust the fluid air at the throttle until fluidization is recognizable.

NOTICE!

The

amount of fluid air depends on the characteristics of the powder. Avoid a build up of

powder dust (too much fluid air) in the powder tank!

7. Close the powder tank and check whether the exhaust air hose is leading in the

direction of the exhaust system of the powder coating booth.

To adapt the programs to the new applications, proceed as described in the EPG-Sprint XE

control unit's operating manual.