39

Super Finish 23 CR

CLEANING THE UNIT

8

CLEANING THE UNIT

A clean state is the best method of ensuring operation with-

out problems. After you have finished work, clean the unit.

Under no circumstances may coating material rests dry and

harden in the unit. The cleaning agent used for cleaning (only

with a flash point above 21 °C) must be suitable for the coat-

ing material used.

Warm water improves the cleaning effect in

the case of water-dilutable coating materials.

For spray work:

Secure the spray gun, refer to the operating

manual of the spray gun. Remove and clean

the tip.

1. Open the discharge tap.

2. Set ON/OFF switch to ON.

3. Turn the pressure control valve back in order to set a mini-

mal pressure.

Only for units with suction system:

Remove suction sys-

tem from material container, leave return hose in material

container until hardly any material escapes. Immerse the

suction system in a suitable cleaning agent.

4. Close the discharge tap.

5. Hold the gun or material ball valve/hose whip in an open

bucket. Pull the trigger on the gun or open the material

ball valve to pump out the remaining material (if appro-

priate, increase the pressure at the pressure control valve

slowly in order to obtain a higher material flow).

The container must be earthed in case of

coating materials which contain solvents.

Caution! Do not pump in a container with

small opening (bunghole)!

See safety regulations.

6. Release the trigger on the gun or close the material ball

cock.

7. Fill up hopper with suitable cleaning agent.

8. Open the discharge tap .

9. Pre-clean the hopper and filter with a brush.

10. Pump suitable cleaning agent in the circuit for several

minutes.

11. Close the discharge tap

12. Hold the gun or material ball cock/whip hose in an open

bucket. Pull the trigger on the gun or open the material

ball cock to pump the cleaning agent out of the hopper.

Do this by pulling and releasing the trigger on the gun

several times/opening and closing the material ball cock.

8.1

CLEANING THE UNIT FROM THE OUTSIDE

First unplug the power plug from the outlet.

Danger of short-circuits caused by water

ingression! Never spray down the unit with

high-pressure or high-pressure steam clean-

ers.

Do not put the high-pressure hose into sol-

vents. Use only a wet cloth to wipe down the

outside of the hose.

Wipe down unit externally with a cloth which has been im-

mersed in a suitable cleaning agent.

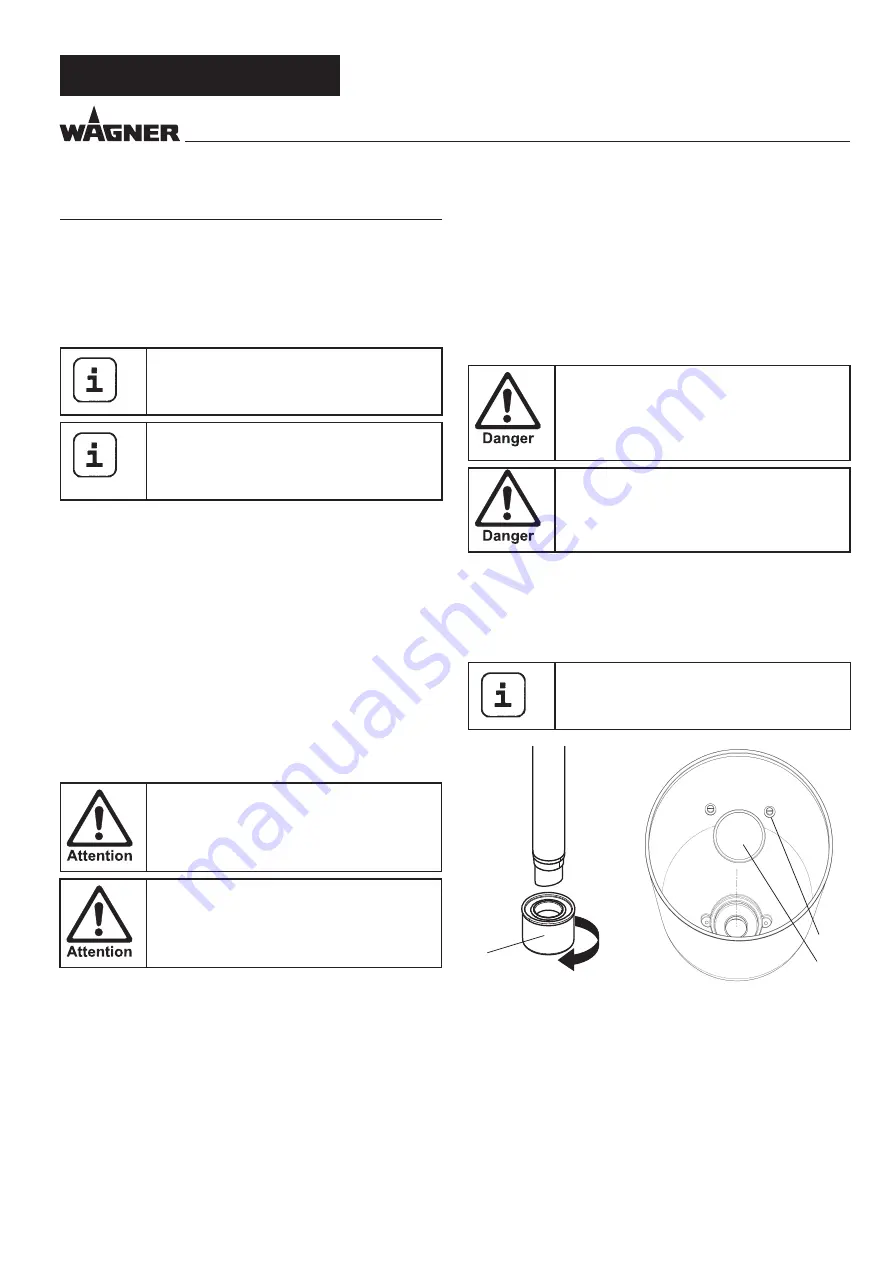

8.2

SUCTION FILTER

Clean filters always ensure maximum volume,

constant spray pressure and problem-free

functioning of the unit.

Unit with suction system

1. Unscrew the filter (Item 1) from the suction tube.

2. Clean or replace the filter.

Carry out cleaning with a hard brush and a correspond-

ing cleaning agent.

Unit with hopper

1. Release screws with a screwdriver (Item 2).

2. Lift and remove filter disk with a screwdriver

3. Clean or replace the filter disk.

Carry out cleaning with a hard brush and a corresponding

cleaning agent.

1

2

1

13. Pour new detergent into the container and repeat the

above procedure 1 or 2 times.

14. Switch off unit

15. Open the discharge tap .