62

Super Finish 23 Select

GB

ITEM ORDER-NO

DESIGNATION

-

0341 265

Hopper 5l, assy.

1

0340 901

Cover

2

0037 607

0003 756

Filter disk, mesh width 0,8 mm

Optional:

Filter disk, mesh width 0,4 mm

3

9902 306

Sheet metal screw 3,9x13 (2)

4

0340 904

Hopper

5

0340 908

Return pipe

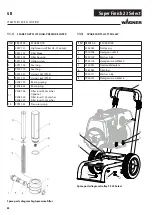

11.6

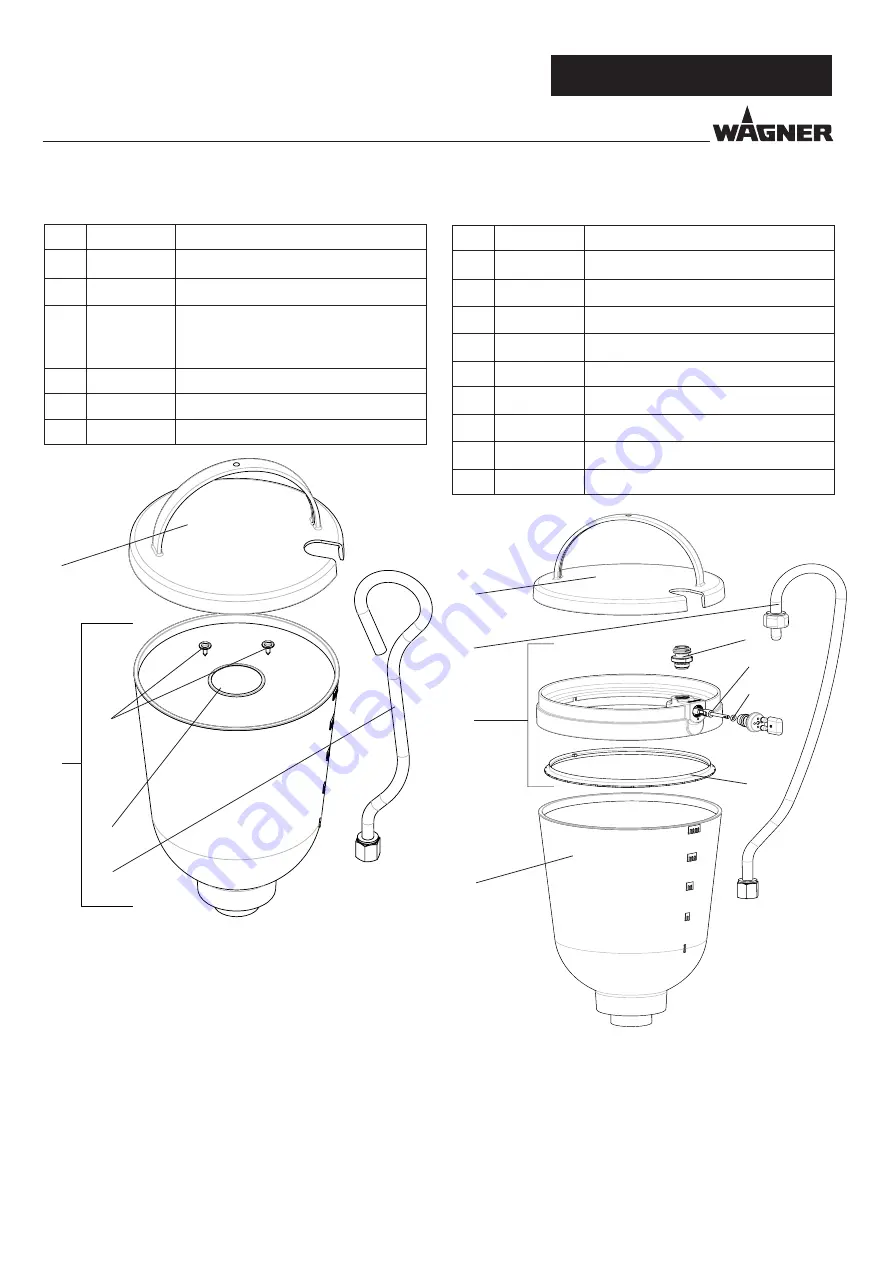

SPARE PARTS LIST HOPPER 5L

Spare parts diagram hopper

3

2

1

4

5

11.7

SPARE PARTS LIST HOPPER WITH TOPCLEAN

ITEM ORDER-NO

DESIGNATION

-

0341 268

Hopper 5l with TopClean, assy.

1

0340 904

Hopper 5l (filter disc see 11.7)

2

0340 901

Cover

3

0340 271

TopClean, assy.

4

0340 270

Return pipe

5

0340 499

Screwing

6

0340 466

Distributor ring

7

0340 500

Rotary valve shaft

8

9971 486

O-ring 4x2 (FFPM)

Spare parts diagram hopper with TopClean

3

4

2

1

5

7

8

6

SPARE PARTS AND ACCESSORIES

Summary of Contents for Super Finish 23 Select

Page 25: ...57 Super Finish 23 Select GB...

Page 35: ...131 Super Finish 23 Select I...