46

Super Finish 33 PRO

GB

4

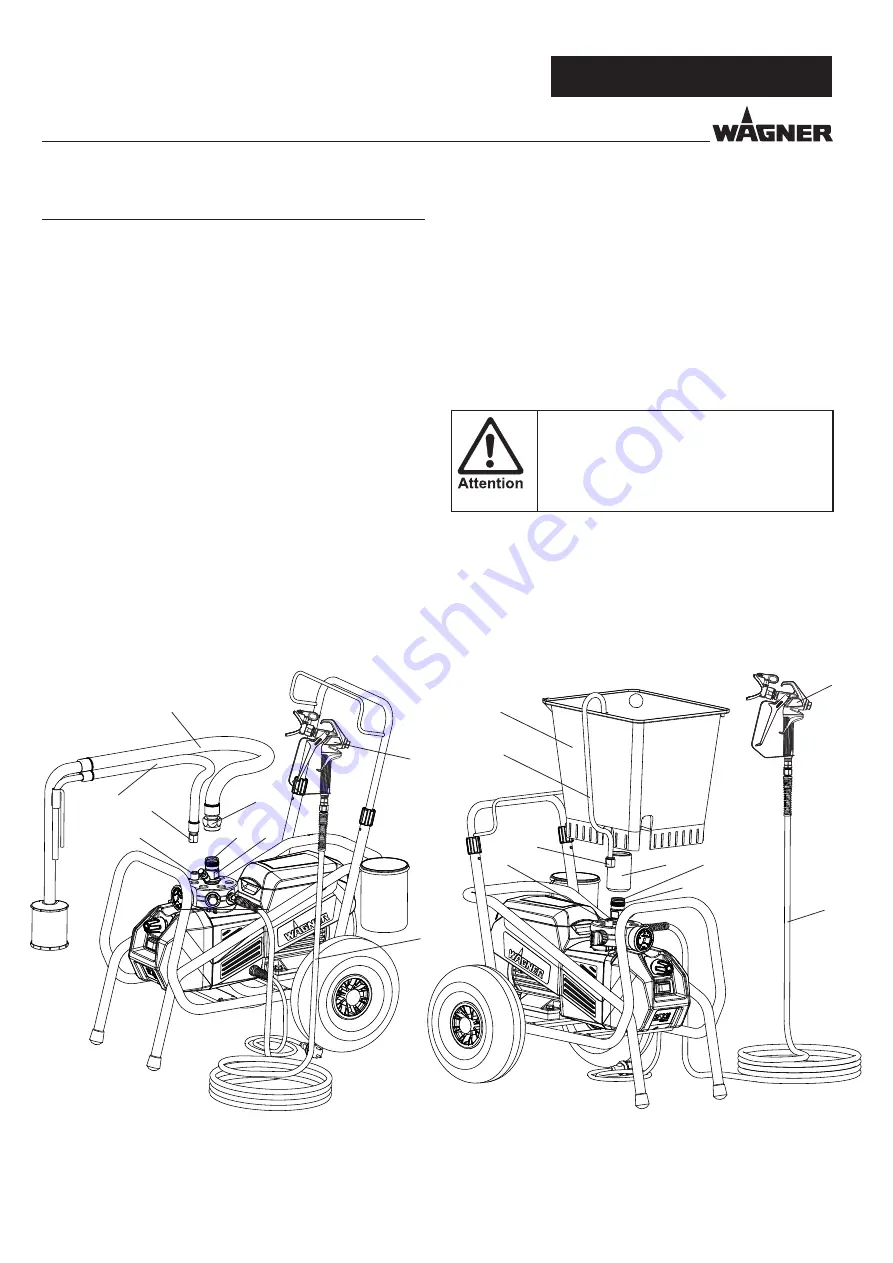

STARTUP

4.1

UNIT WITH SUCTION SYSTEM

1. Ensure that the sealing surfaces of the connections are

clean.

Ensure that the red inlet (1) is inserted in the coating ma-

terial inlet (4).

2. Use the enclosed 41 mm wrench to screw the union nut

(2) at the suction hose (3) onto the coating material inlet

(4) and tighten it.

3. Screw the union nut (5) at the return hose (6) to the con-

nection (7) (22mm).

4.3

HIGH PRESSURE HOSE AND SPRAY GUN

1. Screw the high pressure hose (10) onto the hose connec-

tion

2. Screw the spray gun (11) onto the high pressure hose

3. Tighten all union nuts on high pressure hose so that no

coating material can escape.

4. Screw the tip holder with the selected tip onto the spray

gun, align tip and tighten union nut.

4.2

UNIT WITH UPPER HOPPER

1. Ensure that the sealing surfaces of the connections are

clean. Ensure that the red inlet (1) is inserted in the coat-

ing material inlet (4).

2. Screw the adapter (8) onto the coating material inlet (4)

and tighten until hand-tight.

3. Place the hopper (9) on the adapter (8).

4. Screw the union nut (5) on the return pipe (6) onto the

connection (7).

STARTUP

4.4

CONNECTION TO THE MAINS NETWORK

Connection must always be carried out via

an appropriately grounded safety outlet with

residual-current-operated circuit-breaker (30

mA). An upstream circuit breaker (fuse) with

16 A (B or C characteristics) is required.

Before connecting the unit to the mains supply, ensure that

the line voltage matches that specified on the unit’s rating

plate.

1

4

5

6

7

8

10

1 4

2

3

5

6

7

9

10

11

11

Summary of Contents for Super Finish 33 Pro

Page 21: ...57 Super Finish 33 PRO GB ...

Page 29: ...65 Super Finish 33 PRO GB ...