TITANUS

SUPER·SENS

®

Commissioning

TSS_07_A-en-e Data:

02/09

7

– 9

3. Close the 4.2 mm-air sampling points of the test pipe by means of

adhesive tape after the learning phase.

After approximately 75 s the fault display of TITANUS

®

has to start

flashing.

4. Open the 4.2 mm-air sampling points.

The fault display of TITANUS

®

has to extinguish again.

5. Open the 4.6 mm-air sampling points at the testing pipe.

After about 85 s the fault display of TITANUS

®

has to start flashing.

6. Close the 4.6 mm-air sampling points again.

The fault display of TITANUS

®

has to extinguish again.

For the operational check the diagnostic device or the connection cable

with the diagnostic interface can be used as an option. The following

steps are to be considered:

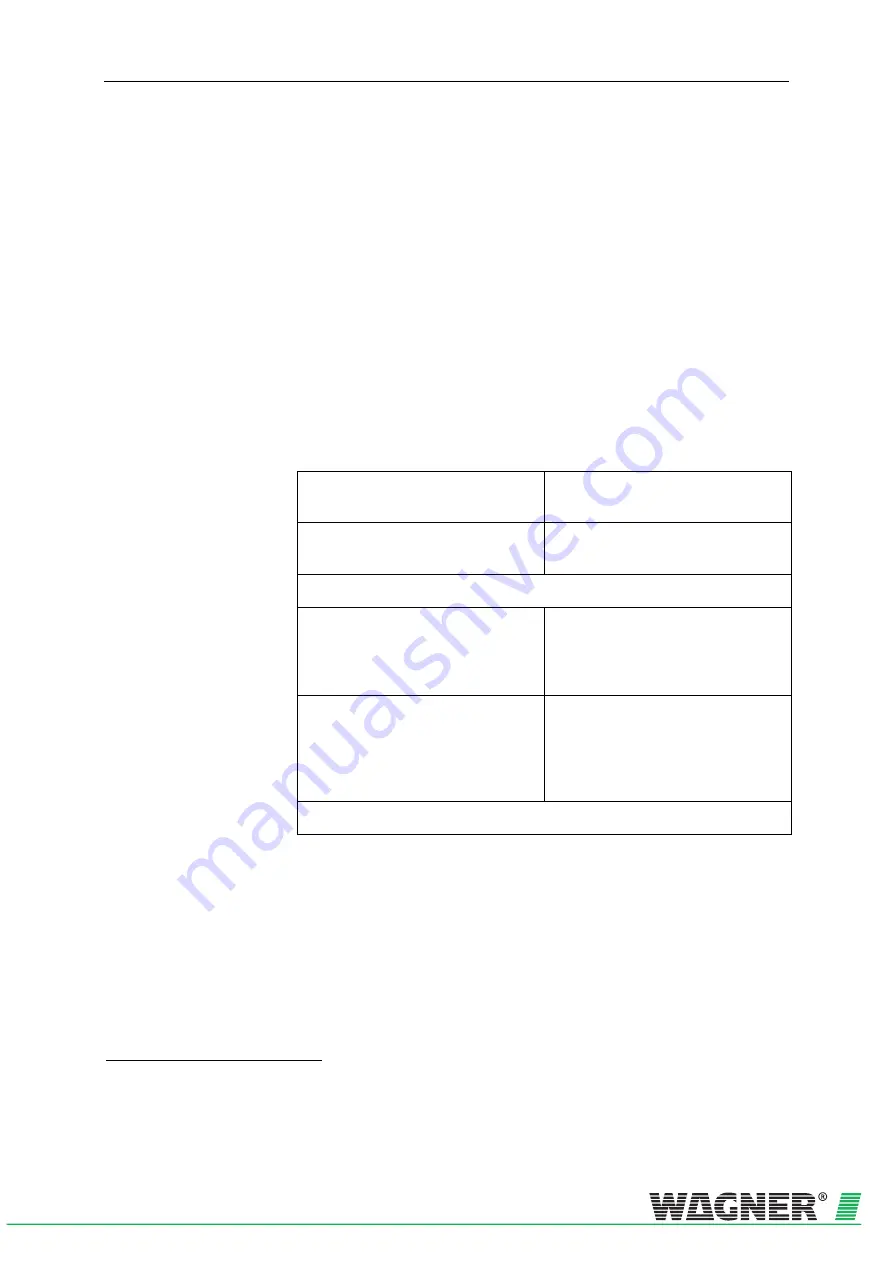

Diagnostic device

Connection cable with

diagnostic interface

1. The diagnostic device is connected to a

PC

1F

1 (COM1, COM2)

1. The connection cable is connected to a

PC

2F

1 (COM1, COM2)

2. The diagnostic program is started.

3. The receiving-LED of the diagnostic de-

vice is put over the infrared-diagnostic

LED of TITANUS

®

and is operated

through pressing the ON-button.

3. The connection cable is connected to

the terminals X 2.16 und X 2.17 with its

remaining end (2 wires).

3a. The display of the diagnostic device is

flashing every second as long as the

device is put over the infrared-LED,

which means as long as data are

transmitted.

4. The current data of TITANUS

SUPER · SENS

®

are visualized on the PC-screen.

After a fault has been eliminated the settings of switch S1 are to be reset

to the original state.

The commissioning is to be repeated from chapter 7.1 "Air Flow Sensor

Adjustment" on.

1 PC with serial interface and WIN 95